An effective remote optical pyrometer focused on the press exit is essential to approach isothermal extrusion and maximize productivity.

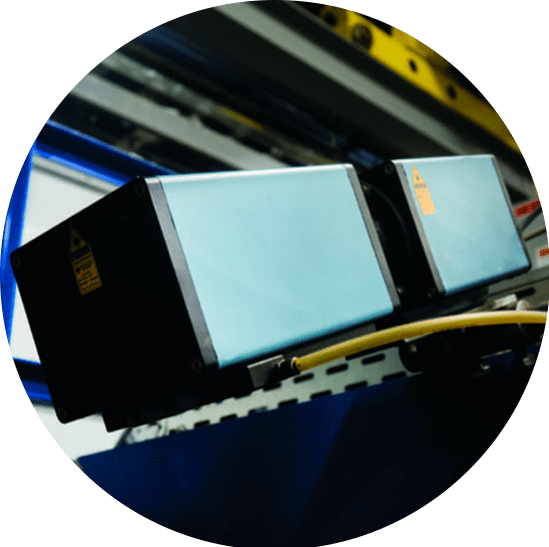

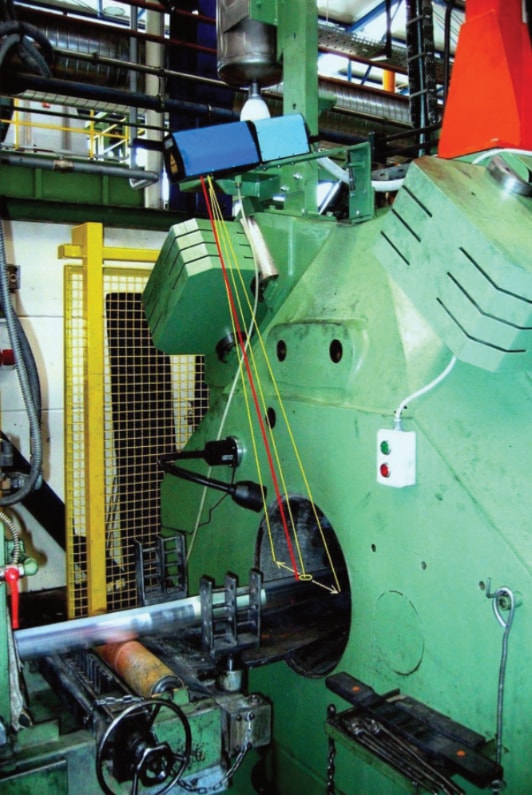

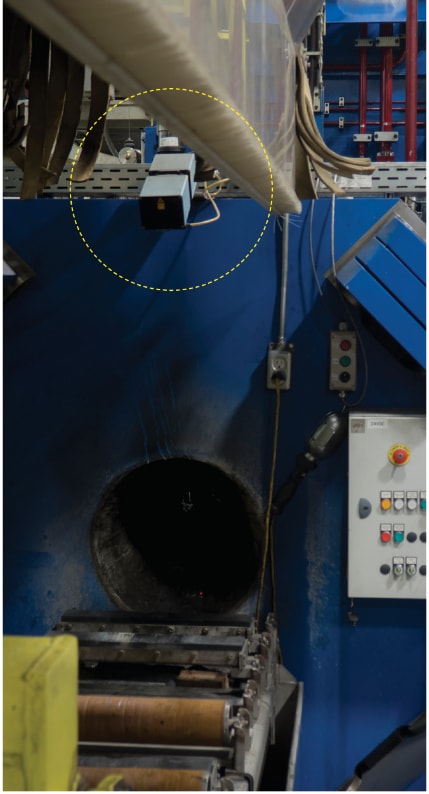

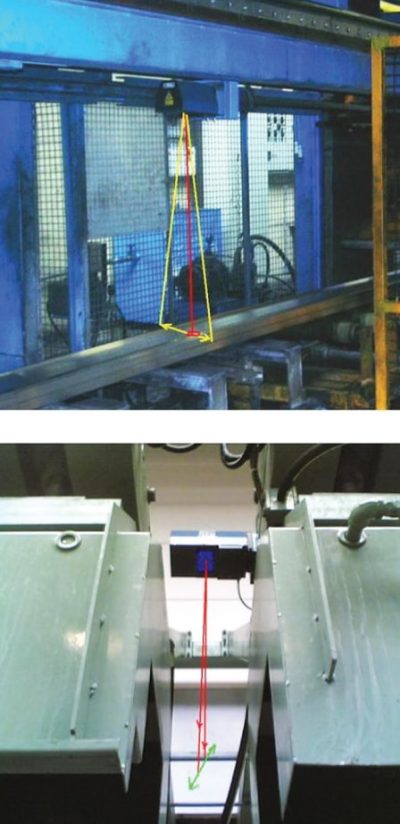

PS3000 Scanning System

AST A4 Scanner

Infrared Thermometer

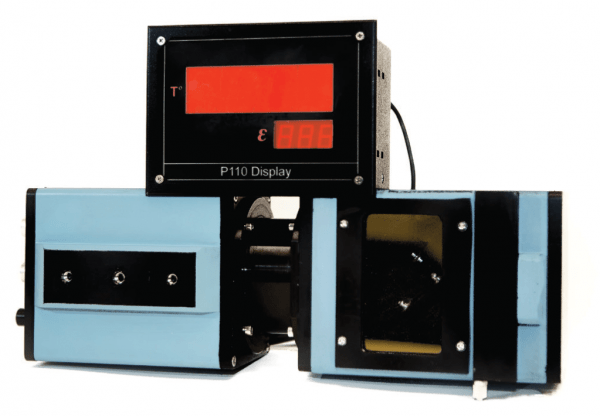

P110 Display Unit

- Plug & Play, simple to install

- Fully automatic tracking

- Manual option of camera aiming

- Allows for continuous reliable temperature measurement

- Tracking of individual profile temperatures in multi-cavity die

FEATURES

- Selection of scanning modes:

- hottest point

- smooth point

- program point (pendulum mode)

- continuous scanning (pendulum)

- Adjustable scanning range up to ± 25º

- Adjustable scanning step from 0.1 – 5º

- Adjustable scanning time

- Minimal working distance 1 meter

- Maximal working distance target size dependence

- Metal processing application for profile, billet, strip and bar

- Simple to use; no calibrations required

- High accuracy; 1% in real site conditions

- Capable of measuring targets with variable emissivity

- Measures through smoke, dust, water vapor, etc.

- Rugged design

- Full range of accessories

- Wide range of built-in functions

PERFORMANCE

- Temperature range: 350 – 850ºC

- Rugged design

- Selection of scanning modes:

- hottest point

- smooth point

- program point (pendulum mode)

- continuous scanning (pendulum)

- Adjustable scanning range up to ± 10º

- Adjustable scanning step from 0.1 – 5º

- Adjustable scanning time

- Minimal working distance 1 meter

- Maximal working distance target size dependence

AC3000 – for aluminum extrusion, hot rolling, continuous casting, forging

- Simple to use; no calibrations required

- High accuracy; 1% in real site conditions

- Capable of measuring targets with variable emissivity

- Measures through smoke, dust, water vapor, etc.

- Rugged design

- Full range of accessories

- Wide range of built-in functions

AC3000 – for aluminum extrusion, hot rolling, continuous casting, forging

- Simple to use; no calibrations required

- High accuracy; 1% in real site conditions

- Capable of measuring targets with variable emissivity

- Measures through smoke, dust, water vapor, etc.

- Rugged design

- Full range of accessories

- Wide range of built-in functions

PERFORMANCE

- Temperature range: 200 – 600ºC (390 – 1110ºF)

- Emissivity range: 0.1 – 1.0

- Response time: 0.1 – 10 sec.

- Default value: 0.5 sec

- Accuracy and repeatability: ± 1%

FEATURES:

- Single channel display

- Displays temperature and emissivity

- Large digits can be seen from a distance

- Weight ~ 0.5 Kg

PERFORMANCE:

- Response time: 51mSec

- Data input: RS422, RS232, RS485

- Optional – AS3000 application selector

- Operating temperature 0 – 45ºC

- Operating humidity 10 – 90% (non-condense)

Purpose

- To measure and control temperature to achieve maximum productivity

Function

- An effective remote optical pyrometer focused on the press exit is absolutely essential in order to approach isothermal extrusion and maximum productivity.

- There is one location where close temperature measurement and control is virtually essential. That is at the exit of the press. Maximum productivity depends on optimum ram speed which can only be achieved with isothermal extrusion. This requires continual and accurate measurement of exit temperature in order to adjust the ram speed accordingly… keeping the exit temperature just below the critical point of surface deterioration.

- Another location where temperature measurement and control is necessary for maximum productivity is at the billet furnace exit, or just before billet loading. This benefits the extruder by ensuring that extrusion begins at optimal temperature for maximum press speed. It prevents a billet that is too hot or too cold from entering the press.

- Every reasonable effort should be made to insure that the billet enters the press at the correct temperature.

- The ability to measure and control temperature to achieve maximum productivity

- Continual and accurate measurement to keep the exit temperature just below critical point of surface deterioration

- Essential in order to approach isothermal extrusion