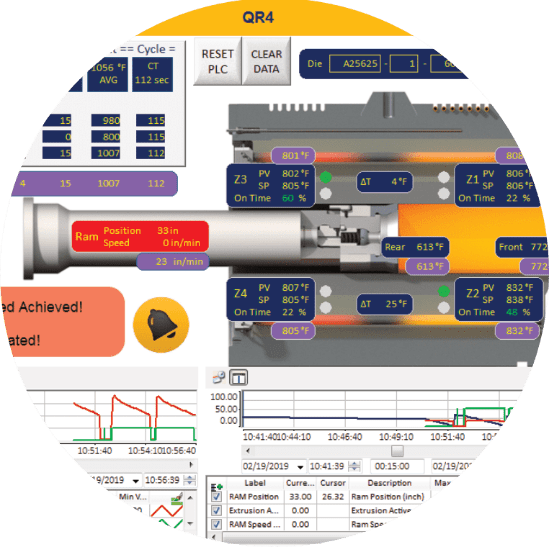

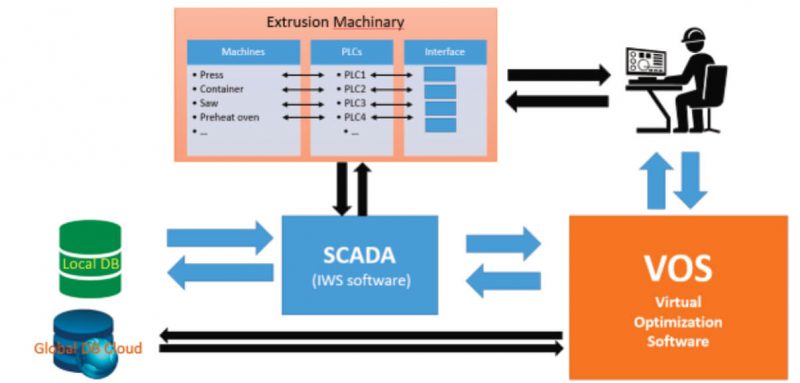

The Visual Optimization System (VOS) puts the press operator in charge by providing tools for extrusion cycle tuning. The system can connect to various PLCs using Scada servers: Press, QR Container, Puller, Die Ovens, Pyrometers, Billet Furnace, Quench, etc.

VOS Create Data Databases

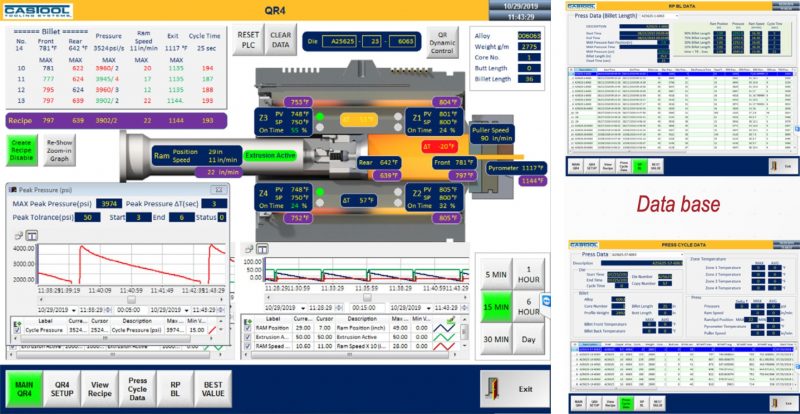

The recipe based visual optimization system is designed to be run at the press. The core strength is the color coded real time comparison to recipe targets.

The recorded data are displayed on the monitor so that the operator can see all the useful data on one screen. VOS can analyze the recorded data for previously extruded billets and recommend better recipe (if applicable) for upcoming billets to improve productivity

- Full data base : pressure, location, speed and temperatures per second; this option takes lots of space but records all the parameters, very beneficial for in-depth and custom analysis of data and research and development purposes but not recommended for all extrusion trials.

- Summarized database: this option summarizes the data just enough to be able to rebuild load curves and temperature history (the required memory for this option is less than 10% compared to full data base)

- Recipe data base : includes given process parameters (ram speed, billet preheat, billet length, material, container set points…) and key information about process and profile such as exit temperature, max. pressure, surface quality and etc.

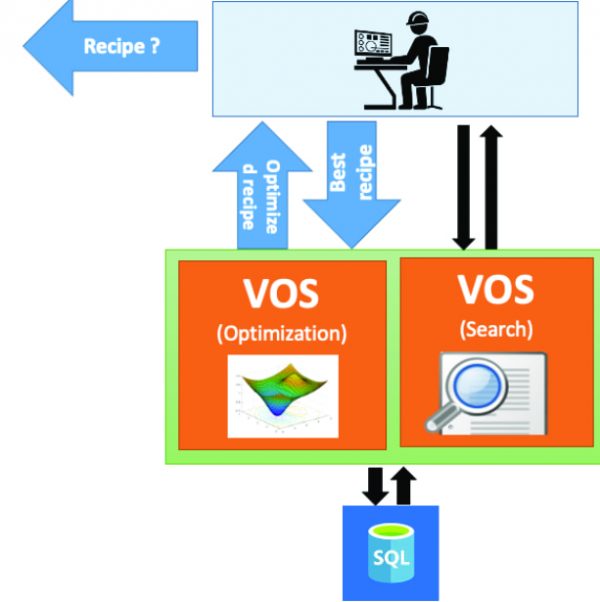

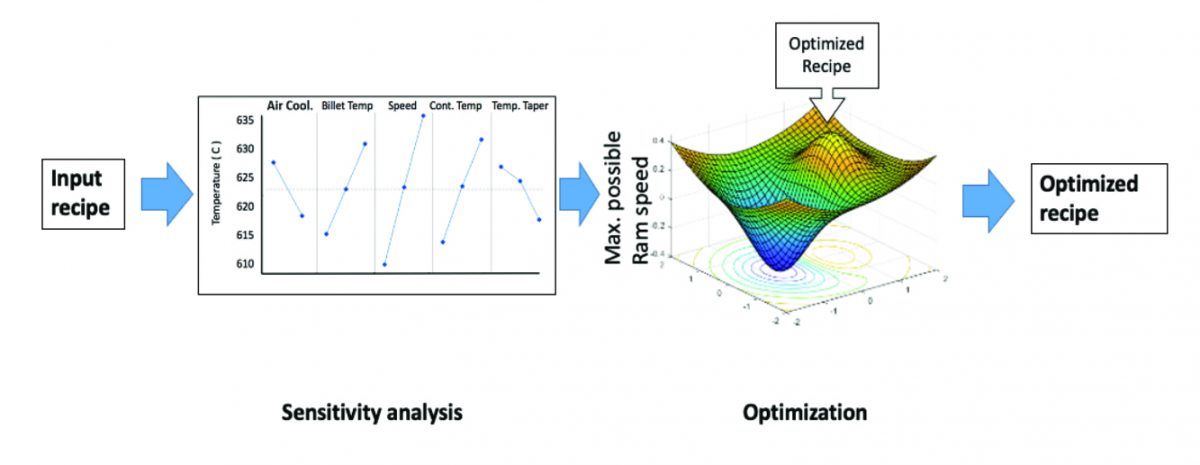

Vos Optimization

- Optimize the best recipe based on given criteria (process parameters, limits,…)

- Predicts quantitative values i.e: exit temperature and load.

- Suggests the optimized recipe to operator to improve productivity.

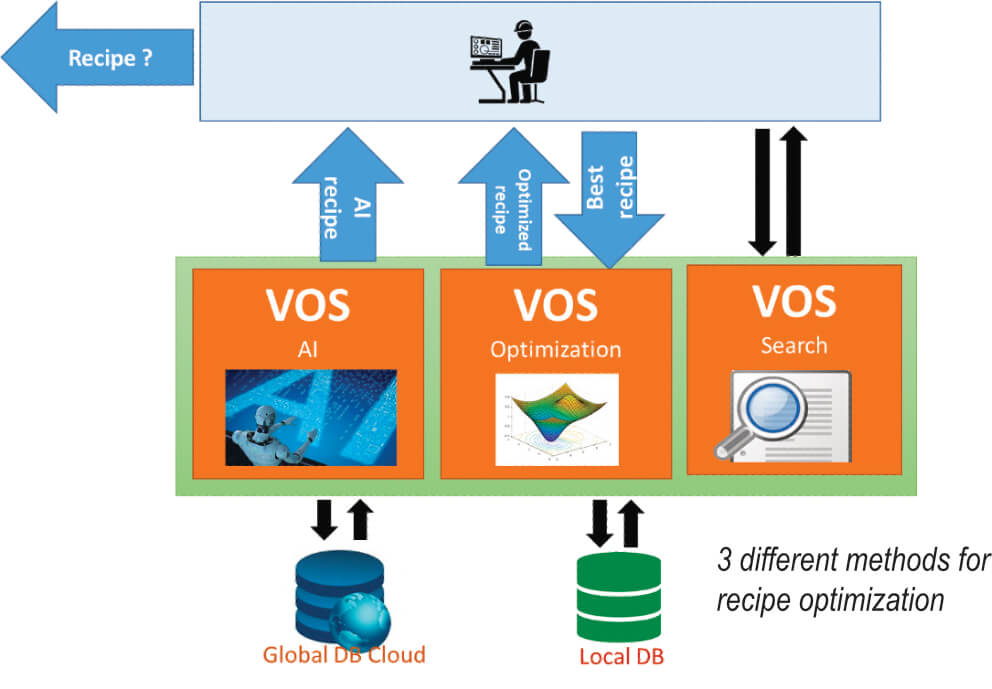

First method is called “Search” that gives the press operator a simple tool to search and select the best recipe used so far for the same or similar die and material. This method does not perform any analysis on the data and just basically provides a search tool within the recipe data base.

The second method, called “Optimization” goes one step further and predicts the “optimum recipe” based on “best practiced recipe” by analyzing the data available in database to calculate the optimum recipe for improving productivity.

For each practiced recipe, VOS will ask for operator feedback on quality of the profile and records the feedback along with recipe. These data will then be used for training an Artificial Intelligence Network to detect the optimum recipe using AI techniques/

- Use AI to choose and optimize the recipe based on big data on cloud

- Improve optimization module so that it can suggest changes to extrusion machinery

Purpose

- Increase production by maximizing ram speed and by using proven recipes

Function

- The system puts the press operator in charge by providing tools for extrusion cycle tuning. The system can connect to various PLC using Scada server : Press, QR Container, Puller, Die Ovens, Pyrometers, Billet Furnace, Quench, etc.*

- RECIPE MANAGEMENT - Add, update, delete recipes - Create recipes specific to profile, copy, alloy and press

- TRACK REAL TIME PRODUCTION STATUS - Ram speed - Zone Temperatures - Temperature Gradients - Current draw

- GENERATE REPORTS - Zone Temperatures, Ram speeds, Current draw, Temperature gradients - Custom reports: Billet Temps, Die change times, Exit temp, Quench rate, etc.

- FEATURES - Track data per billet - Operator prompts for manual optimization - Multiple language support - 19” Industrial PC with pedestal - 1 week onsite support and training - 1 year remote support

- Best recipe selection (search)

- Recipe optimization by sensitivity analysis (Optimization) – under development

- Artificial Intelligence (AI) – under development