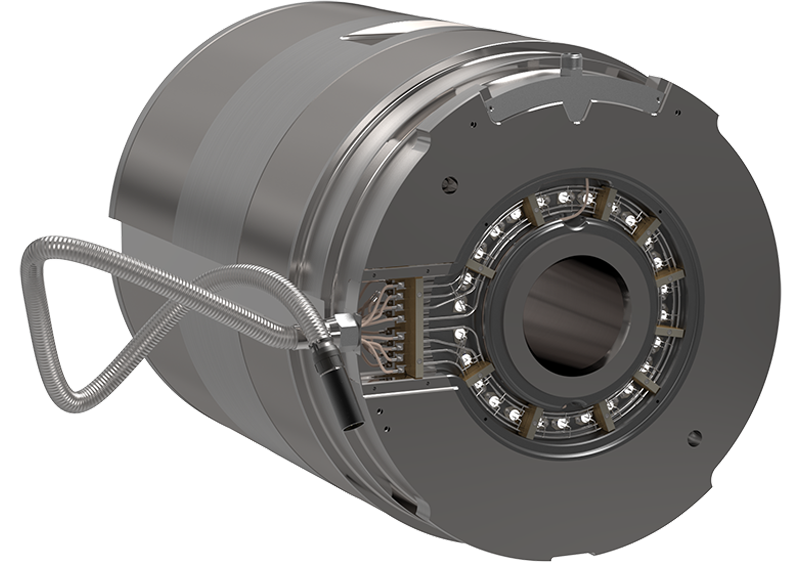

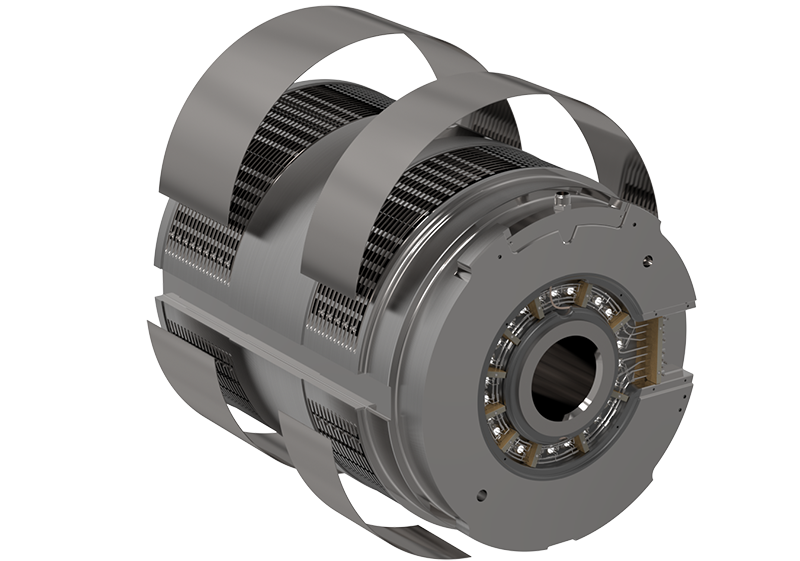

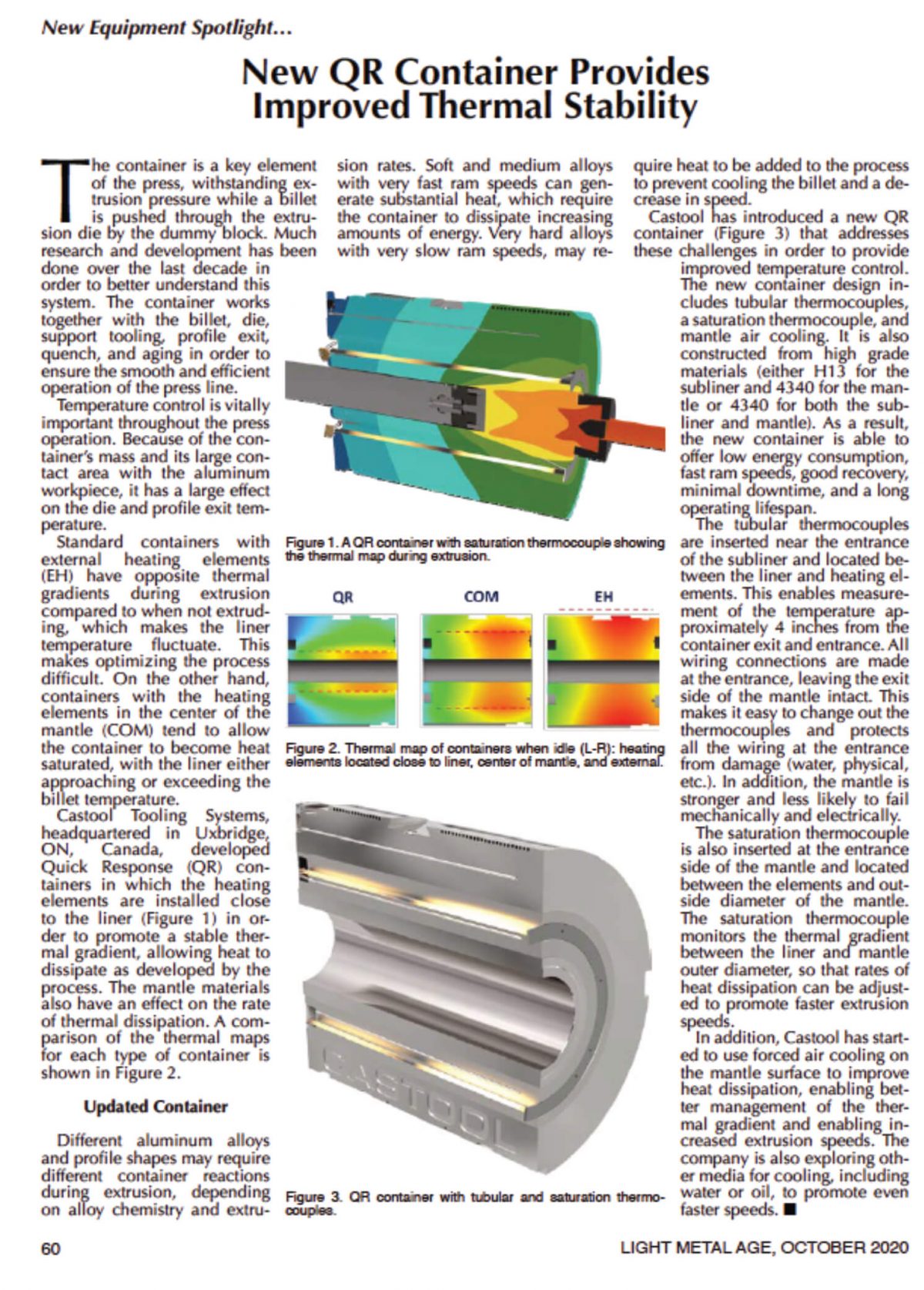

The container withstands extrusion pressure while the dummy block pushes the billet through the extrusion die. Keeping the container thermally and mechanically stable is necessary to ensure the best performance and profile quality. Castool’s Quick Response (QR) Container consumes less energy, has a tougher mantle, has better liner-temperature control and better heat dissipation.

The heating elements and control thermocouples located close to the liner makes the outside of the mantle cooler than the liner, and the container housing even cooler. This maximizes support and mantle life. The built-in thermal gradient allows heat to dissipate from the liner without using auxiliary cooling or air, making it possible to maintain the liner 30oC (50oF) below the billet temperature.

With a QR Container, the response to a demand for heat is therefore almost immediate. The liner is heated when and where necessary; and an improved liner temperature consistency is maintained, which is key to achieving product consistency both metallurgically and dimensionally. The QR Container reduces energy usage by over 50% from standard containers.

The container mantle is made of AISI 4340, which is 100% tougher, and has 80% better thermal conductivity than W.Nr 1.2344 (H-13) or 1.2343 (H-11) steel. This mantle is tougher and has better heat dissipation. The sub-liner is either 4340 or 1.2344 (H-13).The container liner is typically made of 1.2344 (H-13) which has high vanadium carbide and provides superior wear resistance or 1.2367 / E40K / Inconel 718 etc depending on the application.

“It is only when the conversion system, which includes the die, stem, dummy block and container is optimized that maximum productivity can be reached.” Paul Robbins

Purpose

- Maintain liner 30 oC (50 oF) below billet temperature to reduce direct surface inflow onto the profile, reducing scrap from surface finish.

- Increase the billet/container differential towards the back end, and controlling shape, especially waving of wide thin extrusions.

- Reduce container and die slide effect on die temperature and resulting profile run-out, reducing scrap from shape deformation.

- Stabilize container and container housing temperatures which effect hot press alignment.

- Minimize energy usage and extend life of container mantle, liner and dummy block.

Function

- The container withstands extrusion pressure while billet is pushed through the extrusion die by the dummy block. The container maintains liner temperature at +5 oC of desired temperature throughout the process. When using taper heated billets intended for isothermal extrusion and higher productivity, the container liner temperatures can be set appropriately to enable best isothermal extrusion conditions.

- Provides uniform flow of alloy through the die.

- Reduces cost of operation.

- Reduces scrap.

- Reduces downtime.

- Increases productivity.

- Makes isothermal extrusion attainable.

- Increases operating life