Newsletter

POCKET BROCHURE – DIE CASTING

POCKET BROCHURE – EXTRUSION

POCKET BROCHURE – TOOLING

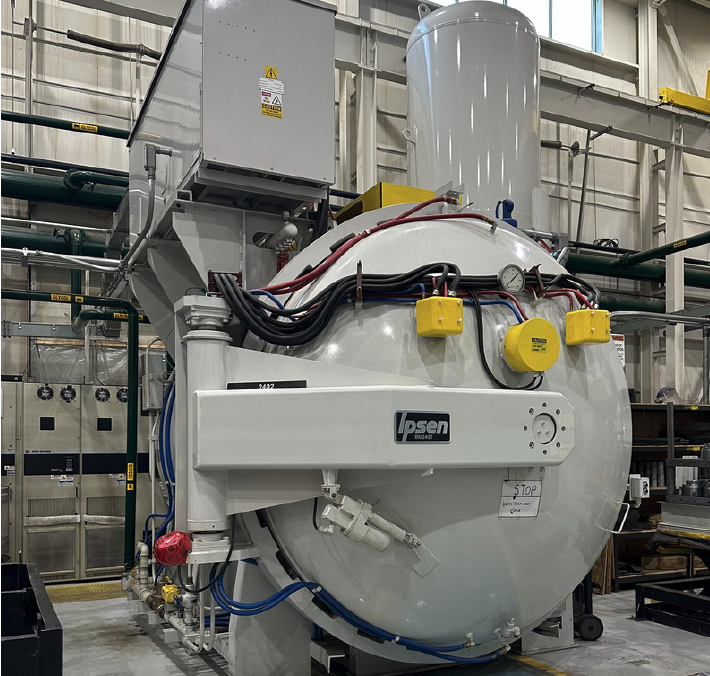

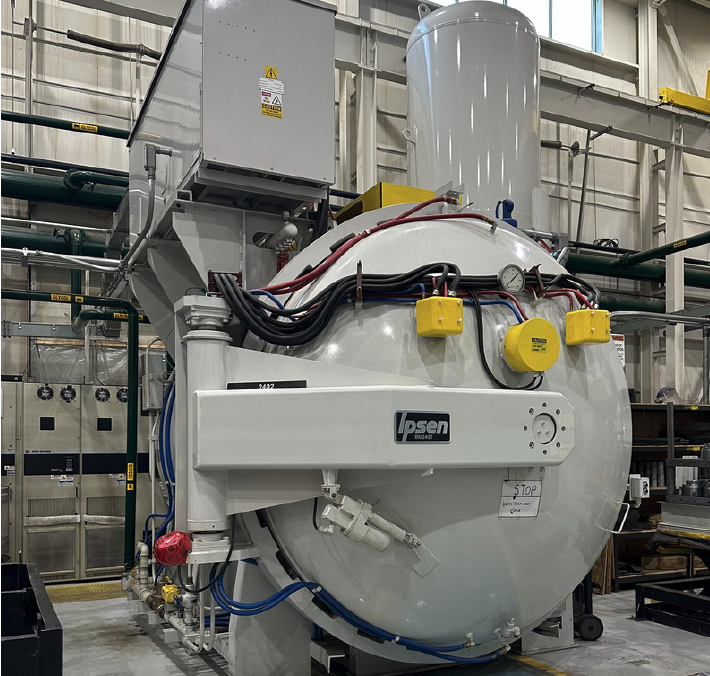

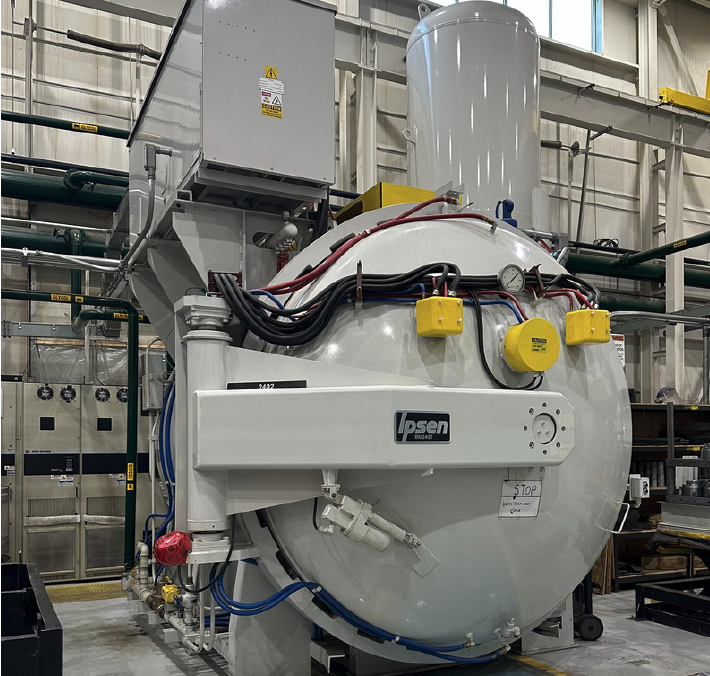

Heat Treatment

The Difference Between Excellence and Mediocrity

Bigger Castings, Bigger Problems: Using Giga Presses to Cast Massive Automotive Parts

Contractor Handbook

Health and Safety Policy

A1.01 Castool IMS Policy 2023

SWP 21 Emergency Response Plan

December 2022 Newsletter

Die Casting Engineer – Bigger Castings Bigger Problems

Extrusion Productivity: Ram Speed/Die Design/Container

Plunger Tip Evolution in the Diecast Industry

Better Profiles Faster: Material Selection for Extrusion Tooling

Material Selection for Extrusion Containers

Material Selection for Extrusion Tooling – Part III

Better Castings Faster: Tooling Material, Process and Failure Analysis in Diecasting

Material Selection for Diecast Tooling: Decision Theory and Practice

Extrusion Productivity: Billet Geometry/Container/Dummy Block

Better Profiles Faster: Material Selection for Extrusion Tooling

A Fine Balance: The Difference between Excellence and Mediocrity

May 2022 Die Casting Engineer

CTS Insider – March 2022

Foundry

Billet Geometry – Japanese

Additive Manufacturing

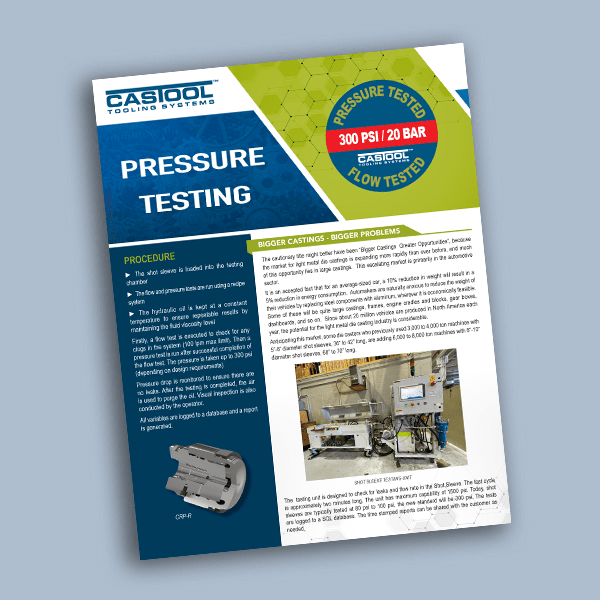

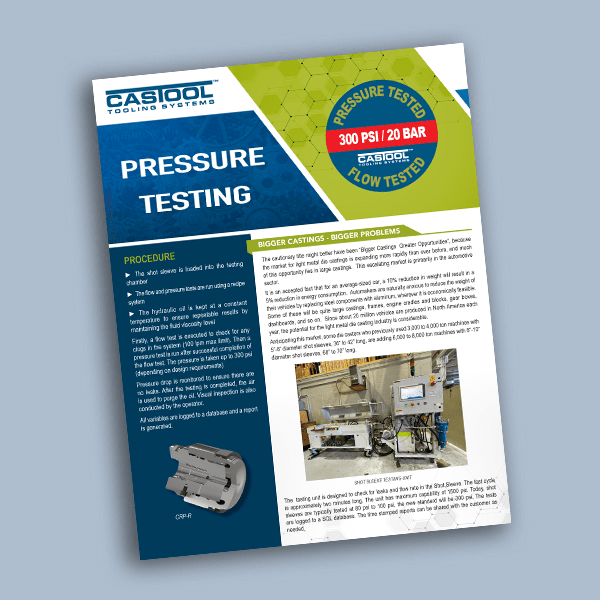

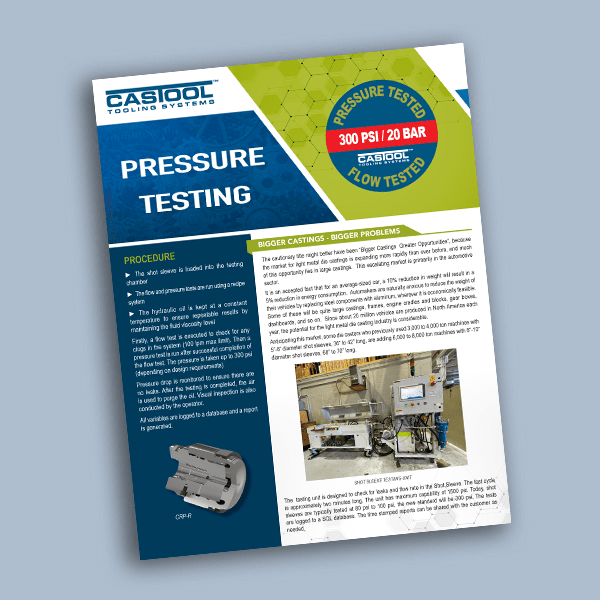

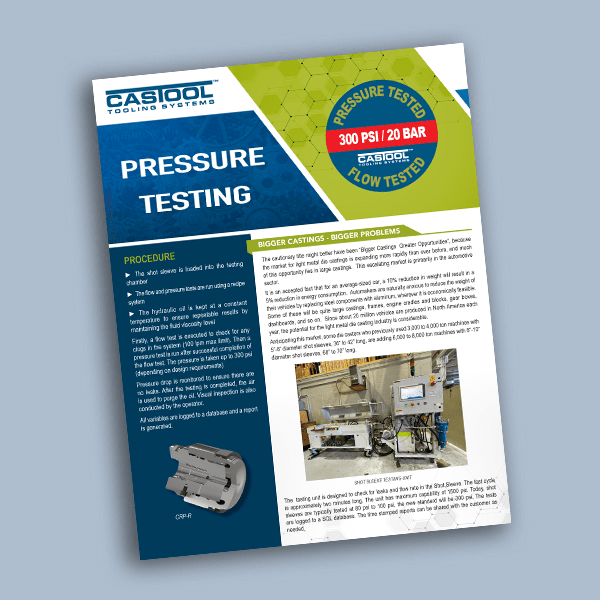

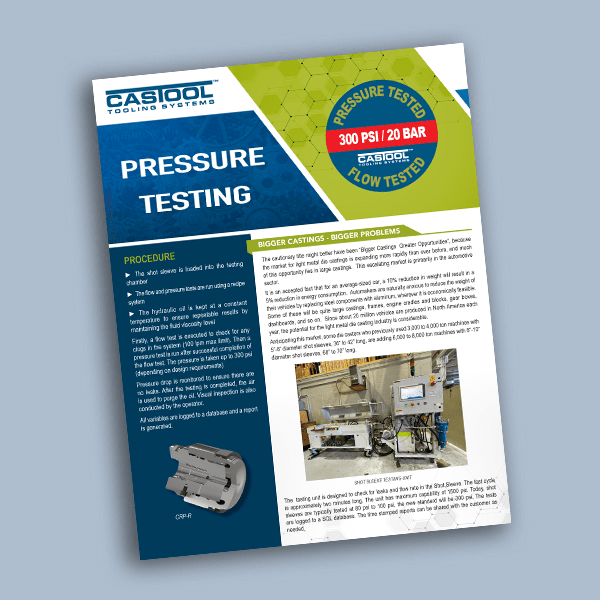

Pressure and Leak Testing

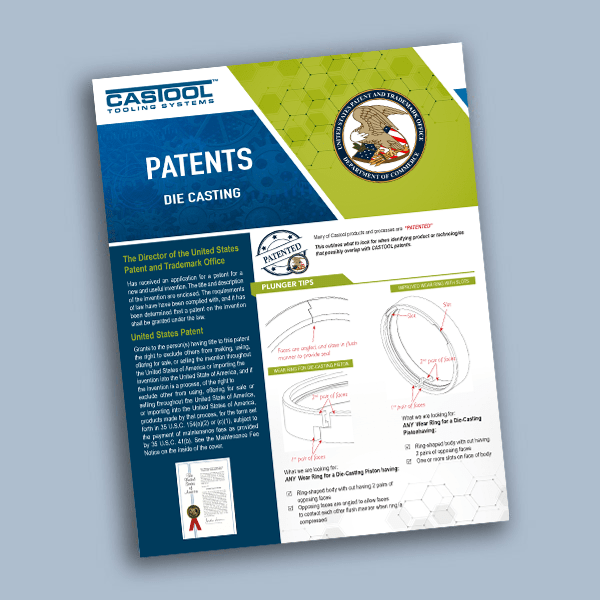

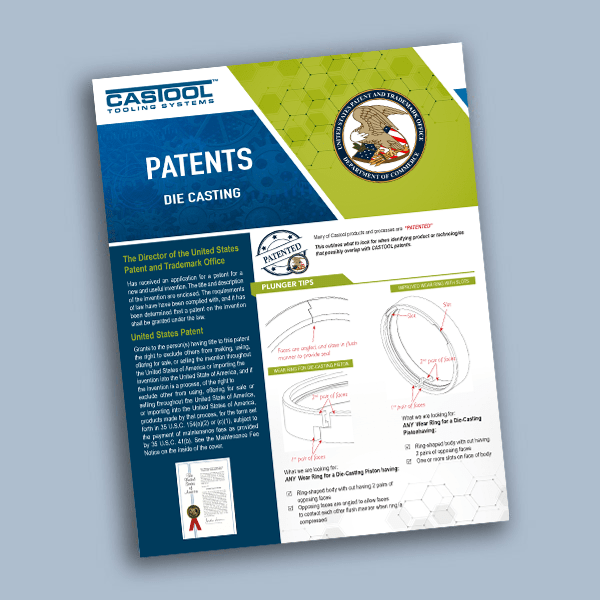

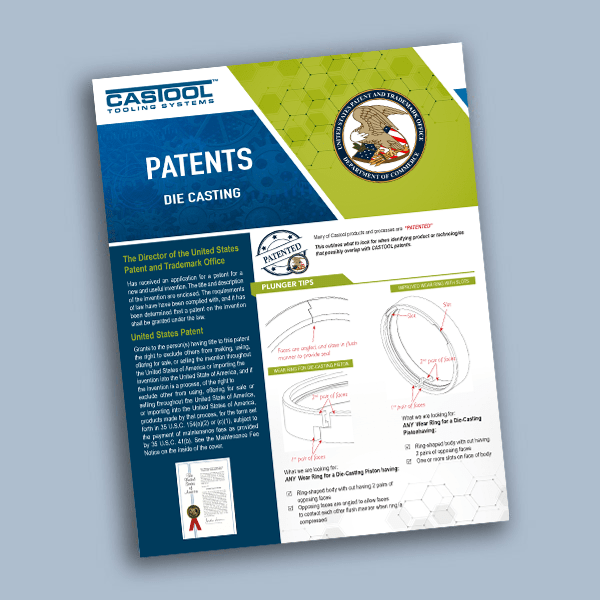

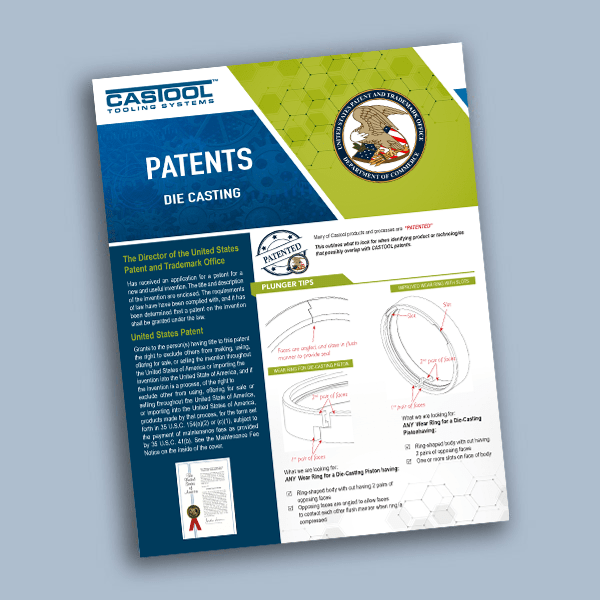

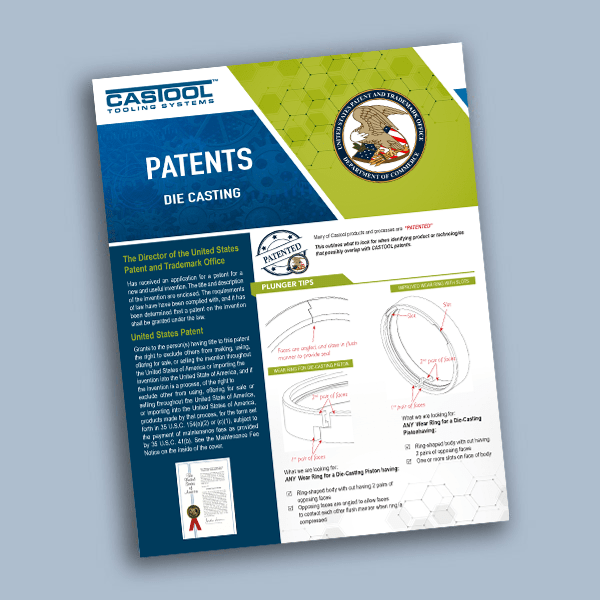

Patents Die Cast

Visual Optimization System

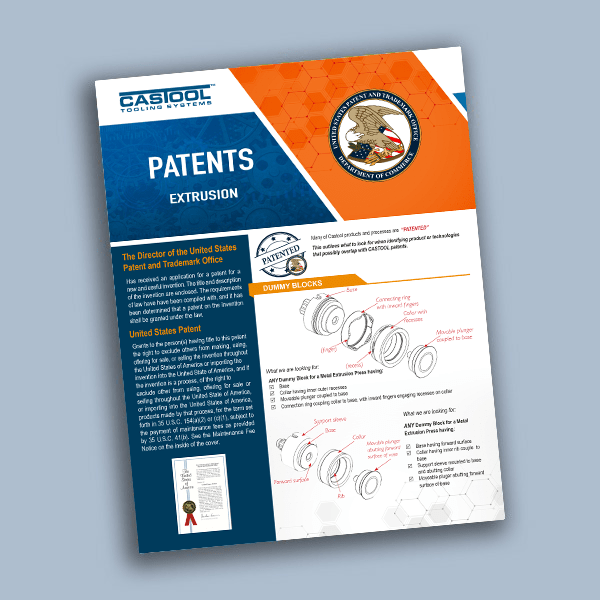

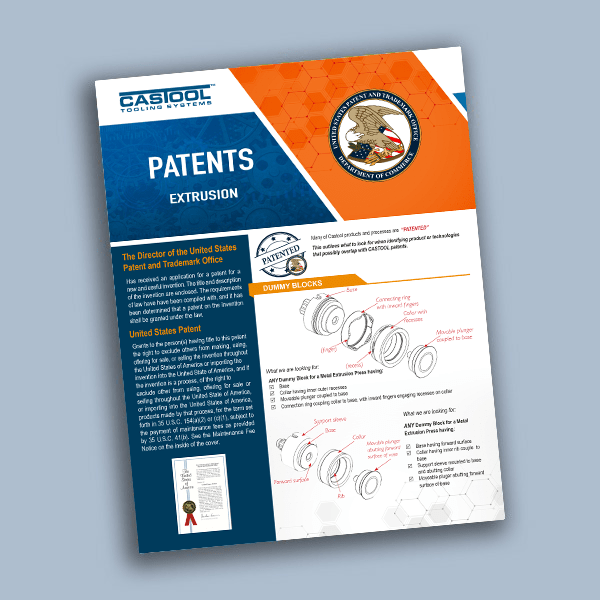

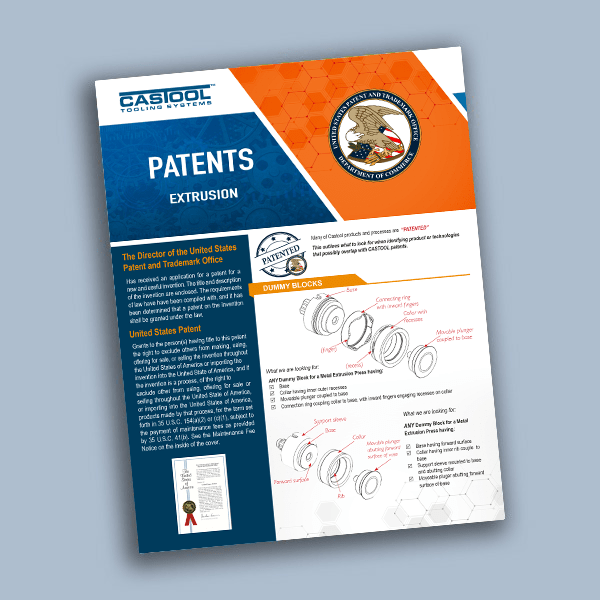

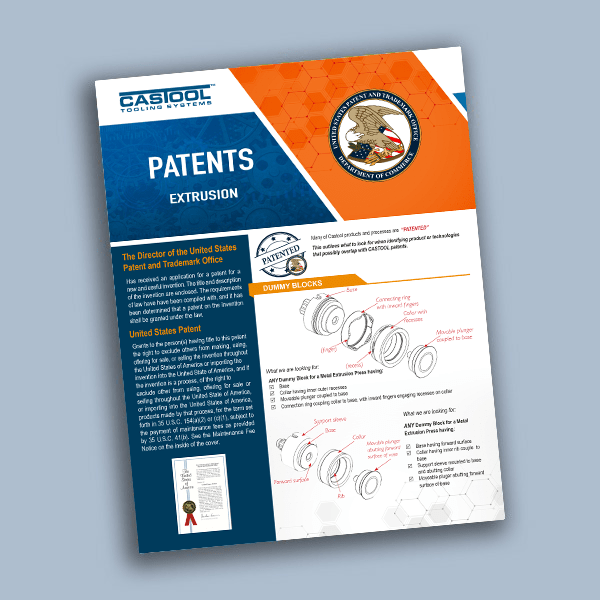

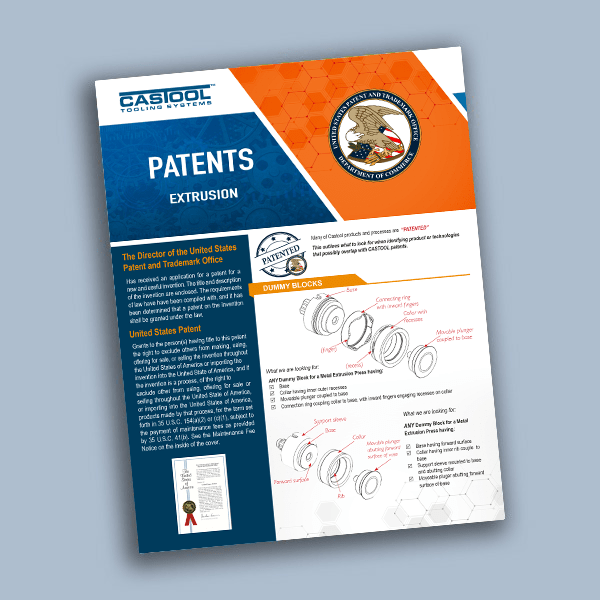

Patents Extrusion

Tooling

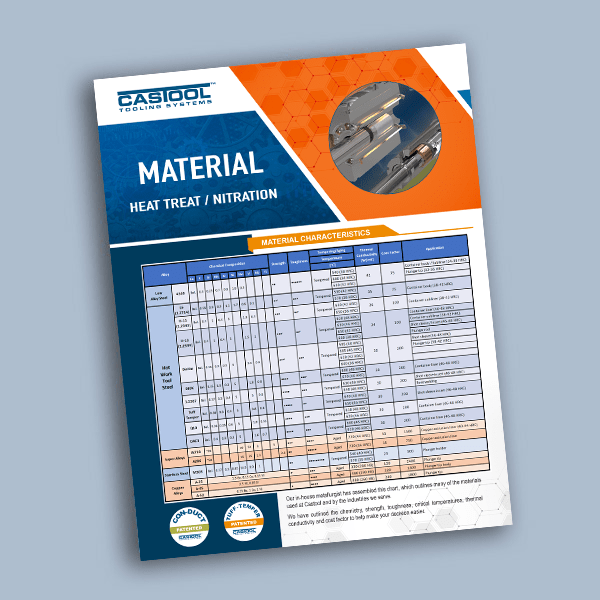

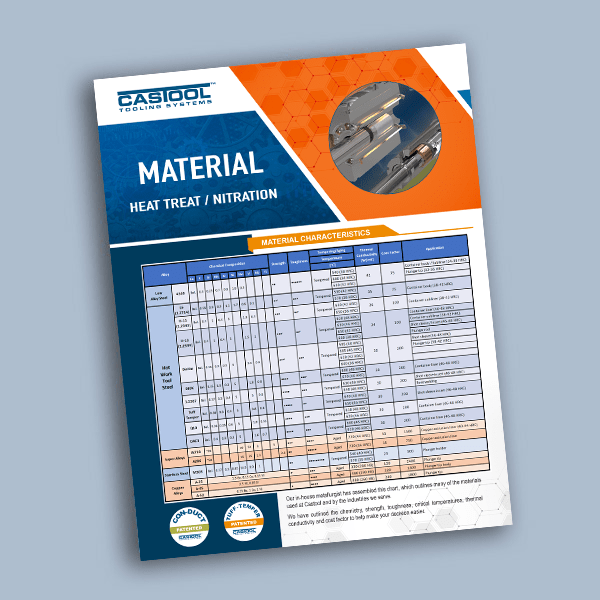

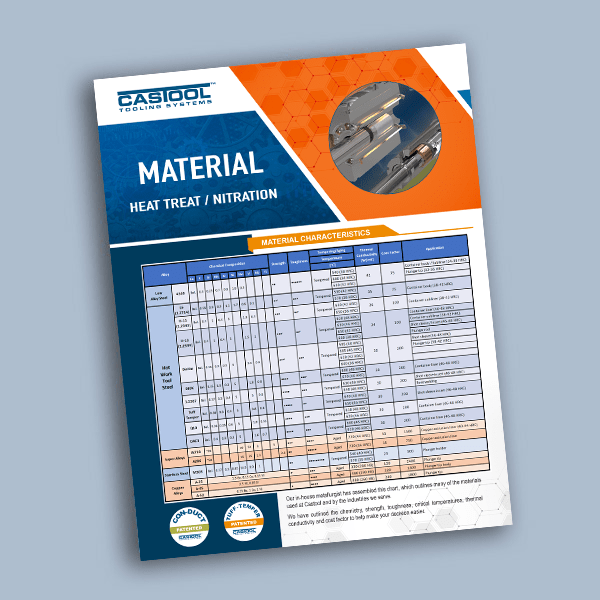

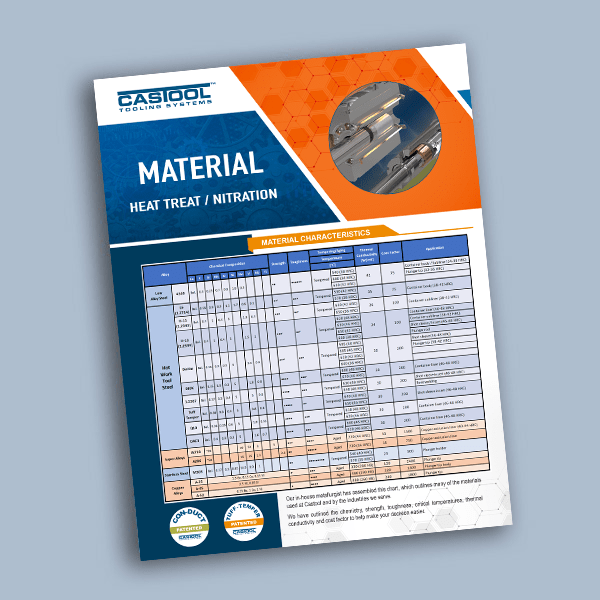

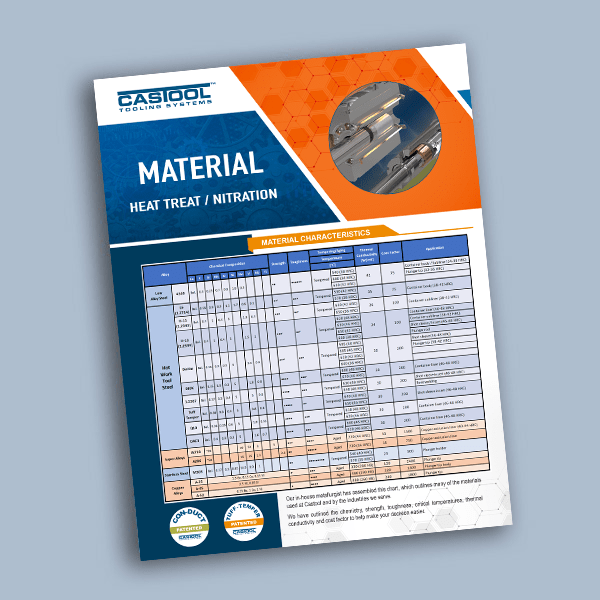

Materials

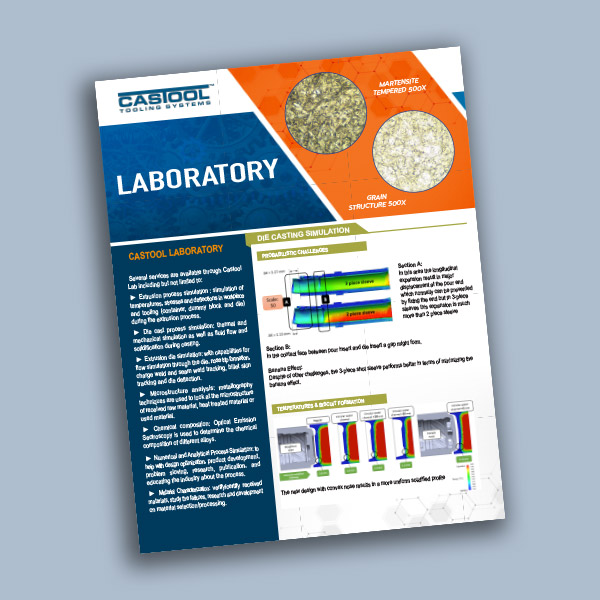

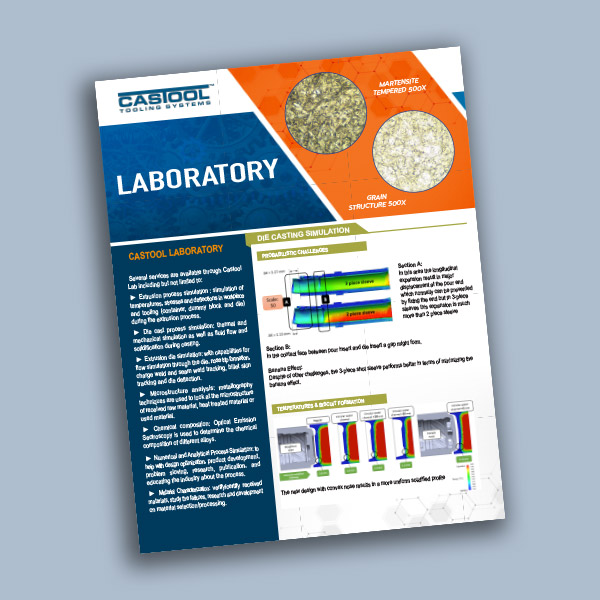

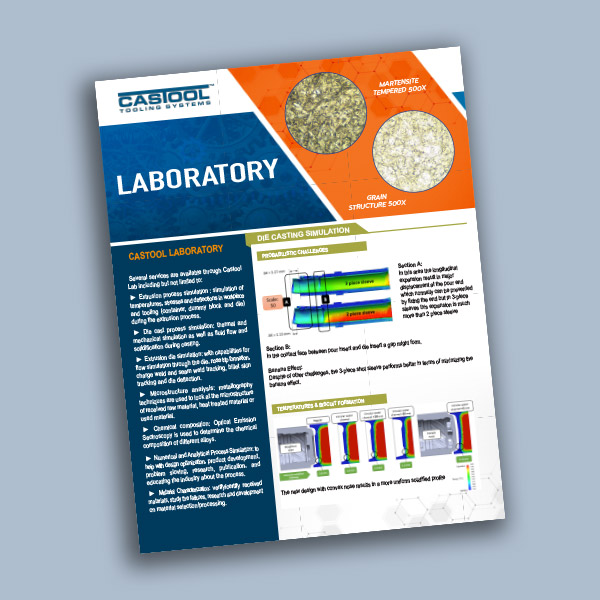

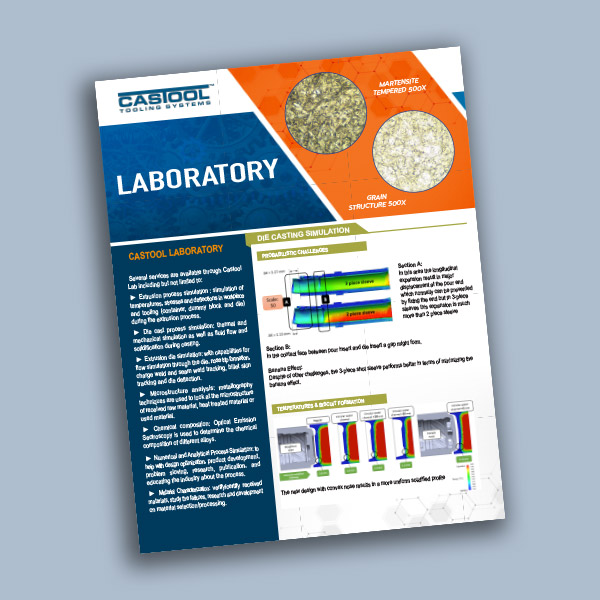

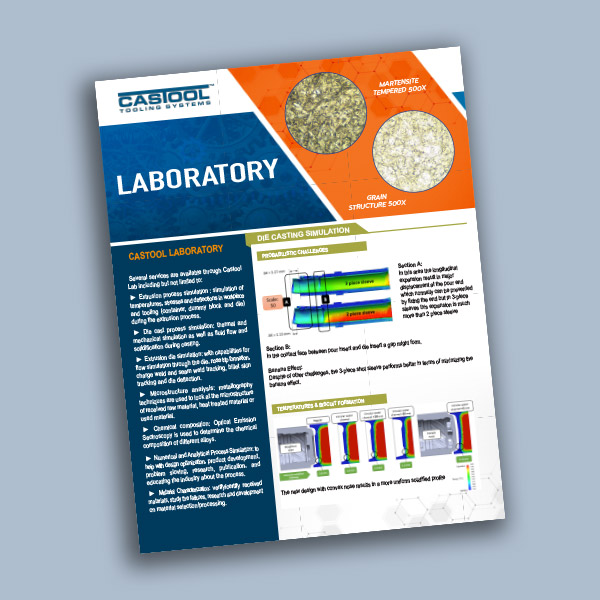

Laboratory

CTS Insider – March 2021

Castool Laboratory

Castool Ring Plunger – CRP – Plunger Tips

Lubricants Liquid CLS200

Plunger Tips CRP

Alu Ject

CTS Insider – Summer 2020

CTS Insider – Spring 2020

CTS Insider – Winter 2020

ISO 14001 2015-Environmental

ISO 9001 2015-Quality

CTS Insider – Summer 2020

CTS Insider – Spring 2020

Fine Balance – The difference between excellence and mediocrity (Japanese)

Plunger Tips

Plunger Tips ARP

Extrusion Productivity Part II – Predicting of Ram Speed (Japanese)

CTS Insider – Winter 2019

CTS Insider – Fall 2019

CTS Insider – Summer 2019

CTS Insider – Spring 2019

Extrusion Productivity Part II – Predicting of Ram Speed

CTS Insider – Fall 2018

CTS Insider – Summer 2018

CTS Insider – Spring 2018

CTS Insider – Winter 2018

The Realities of Being a Superextruder Today

Stems

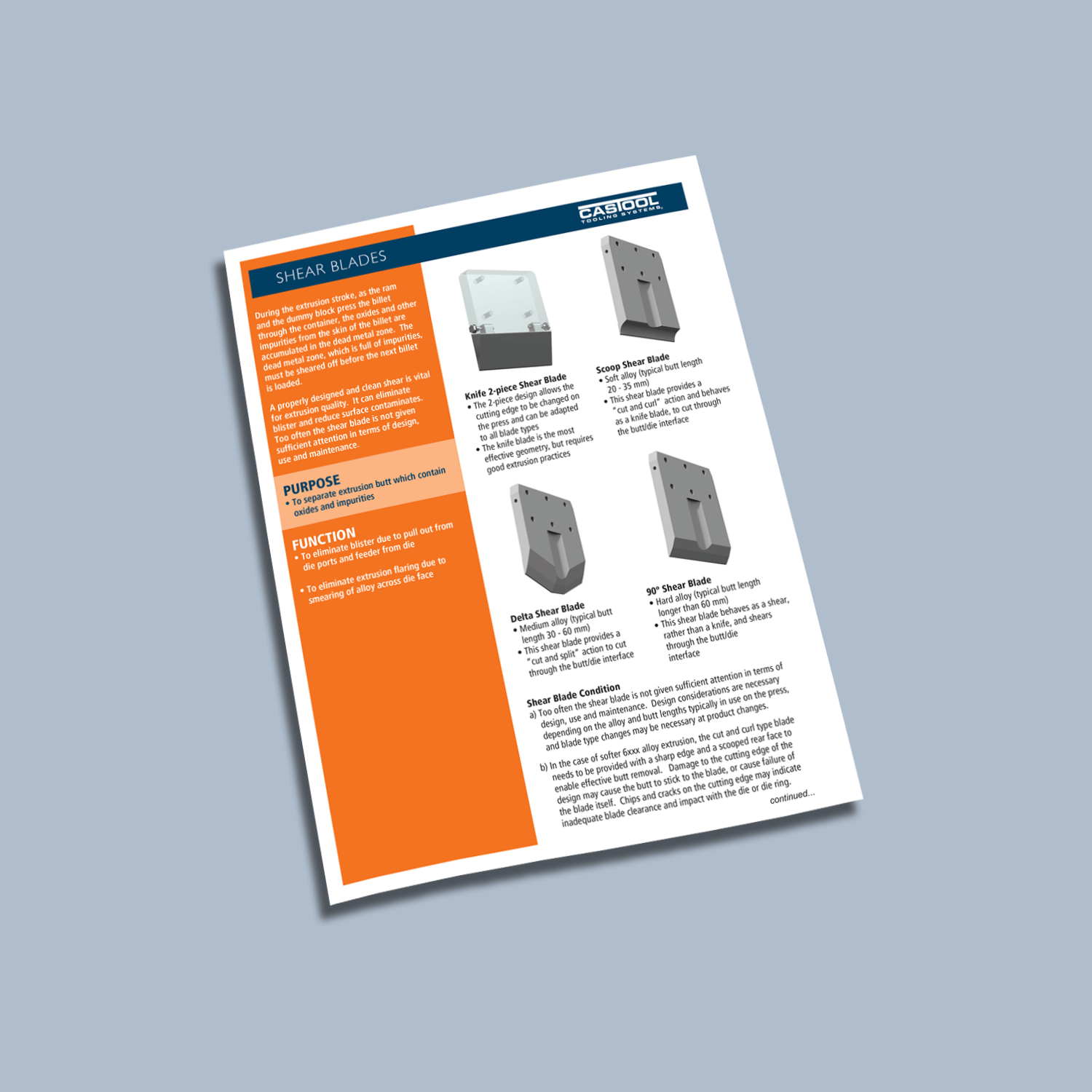

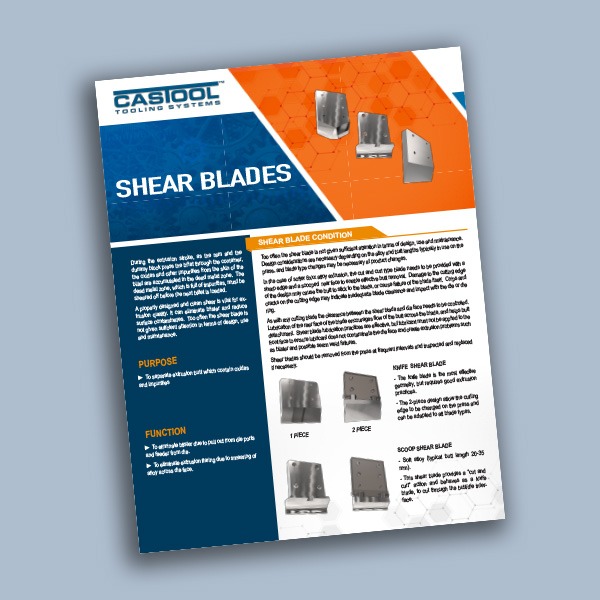

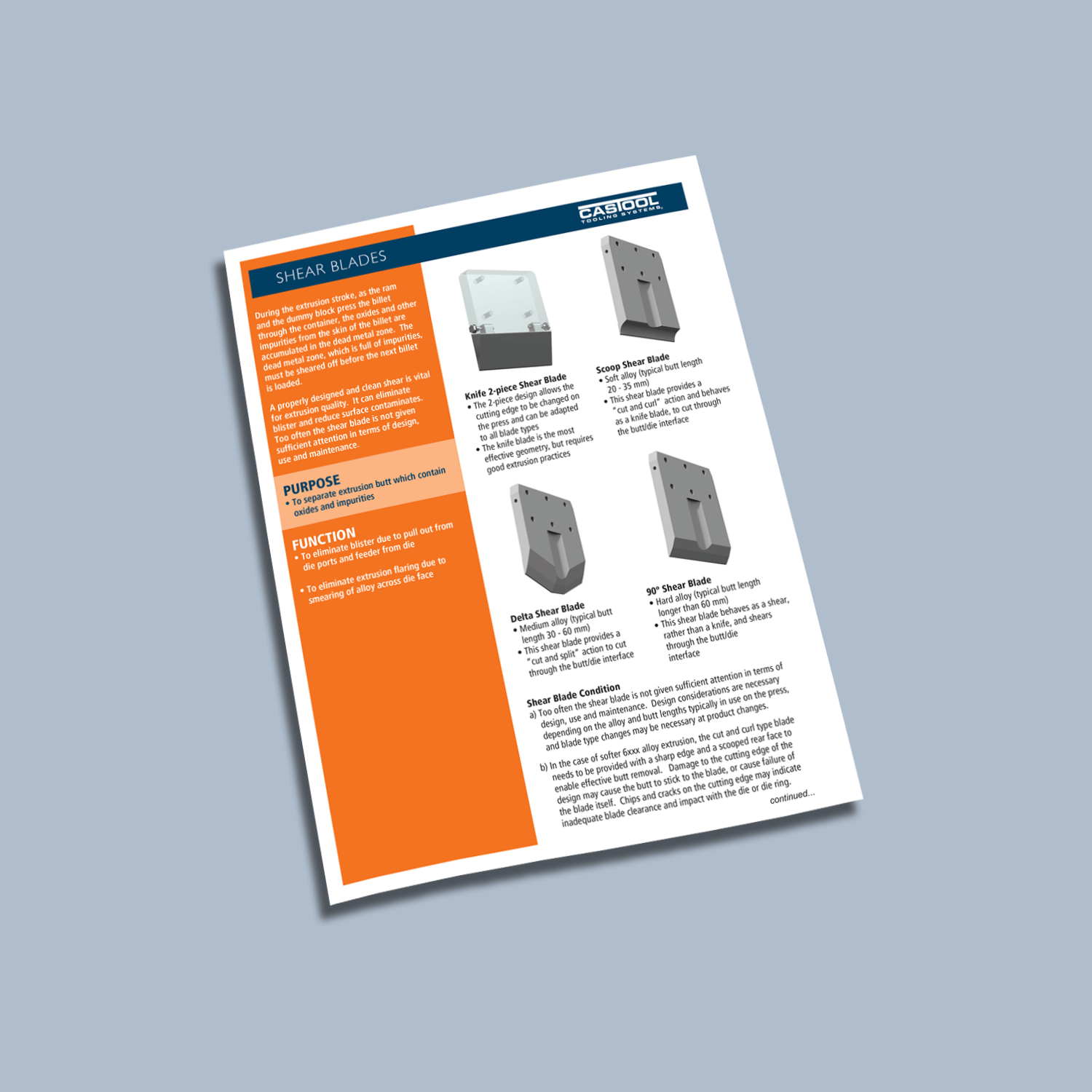

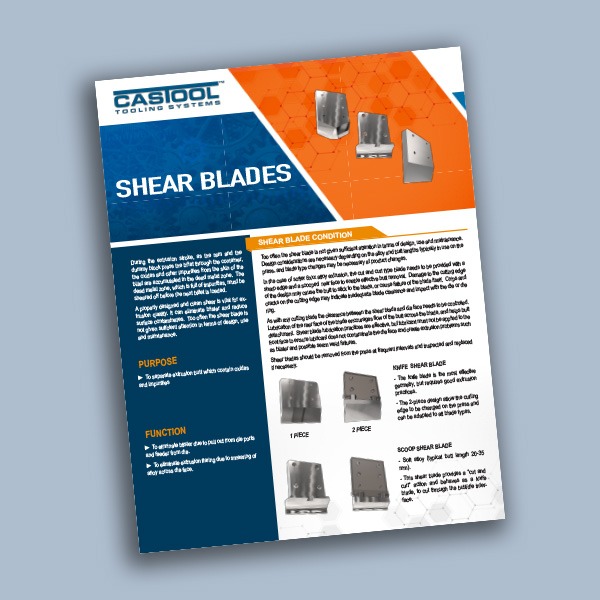

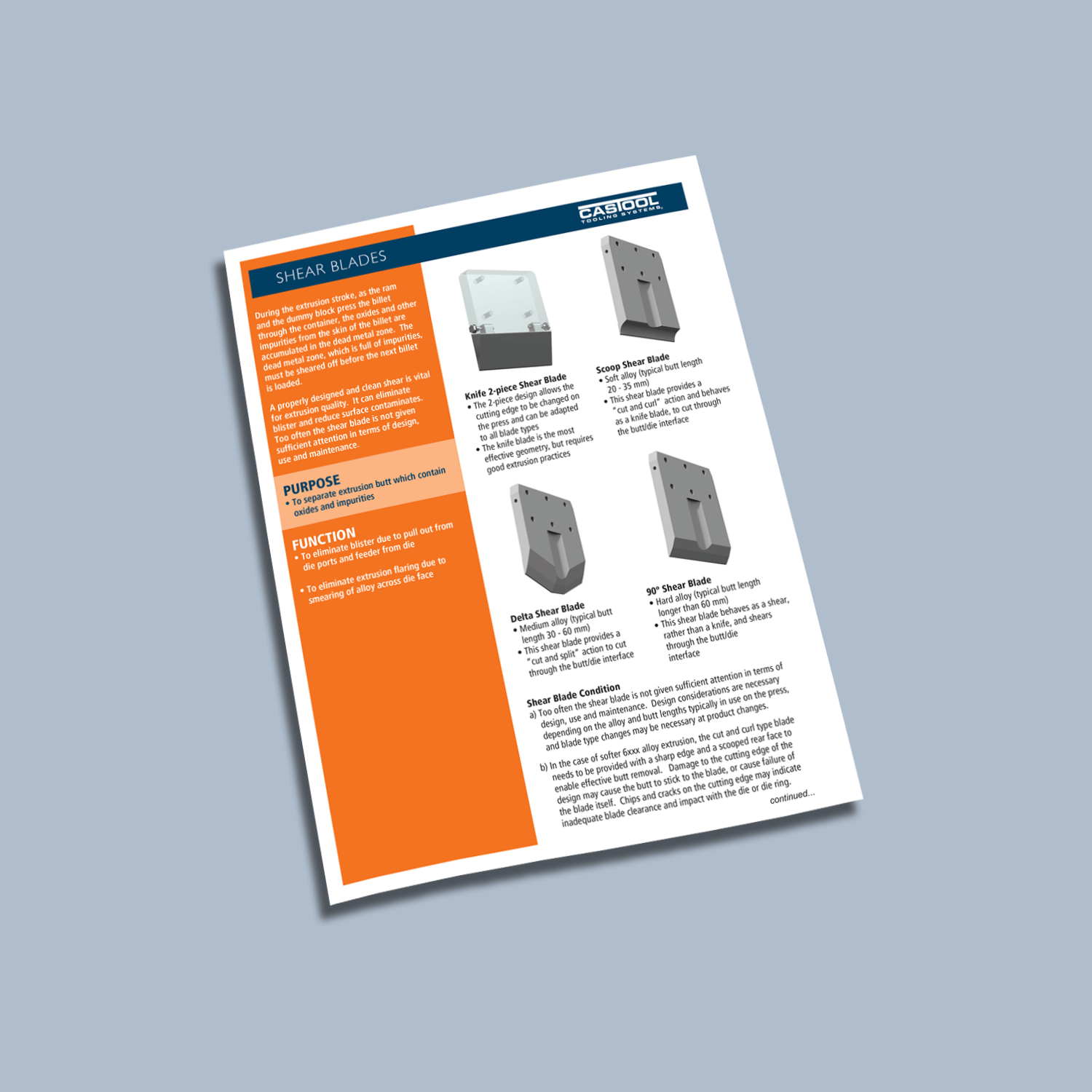

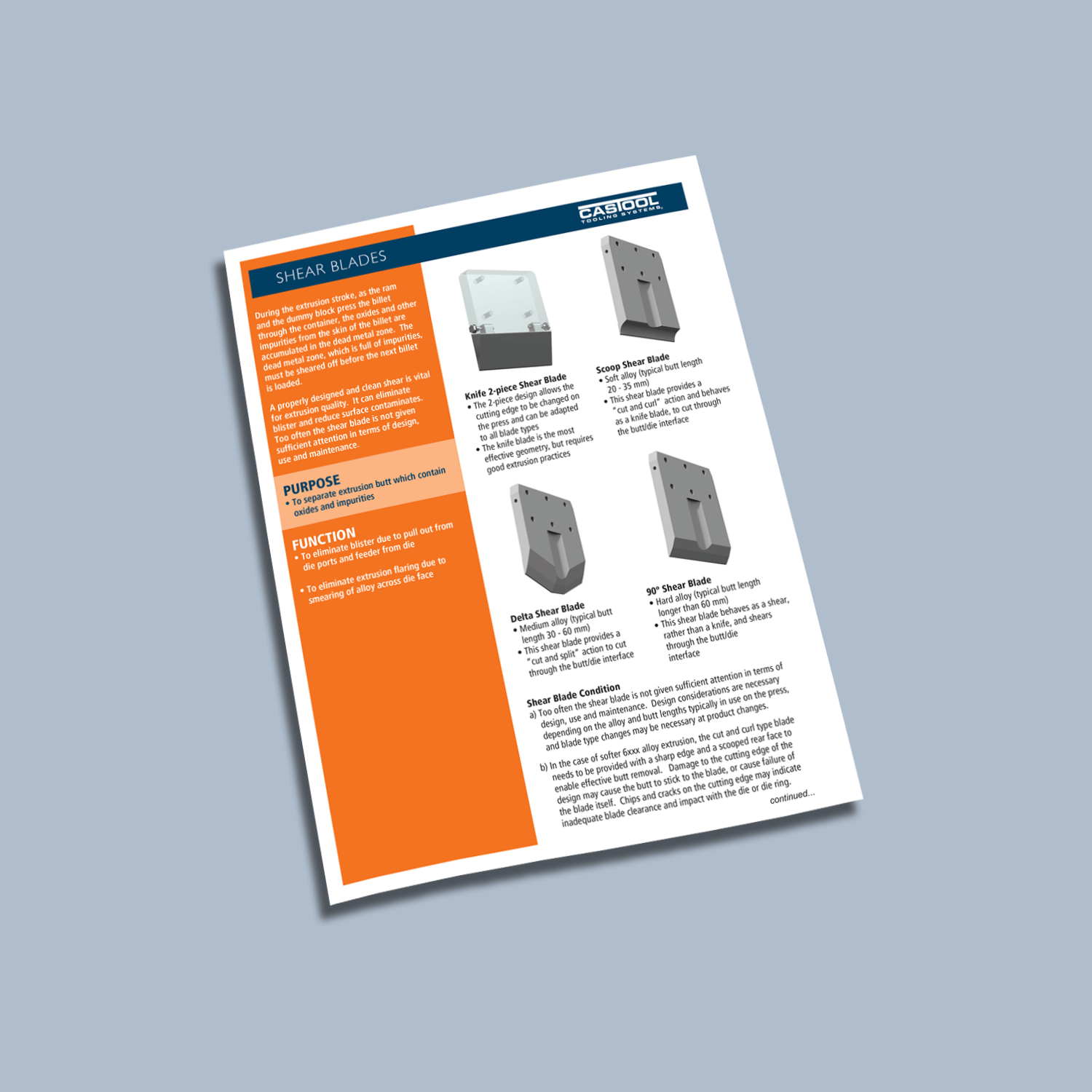

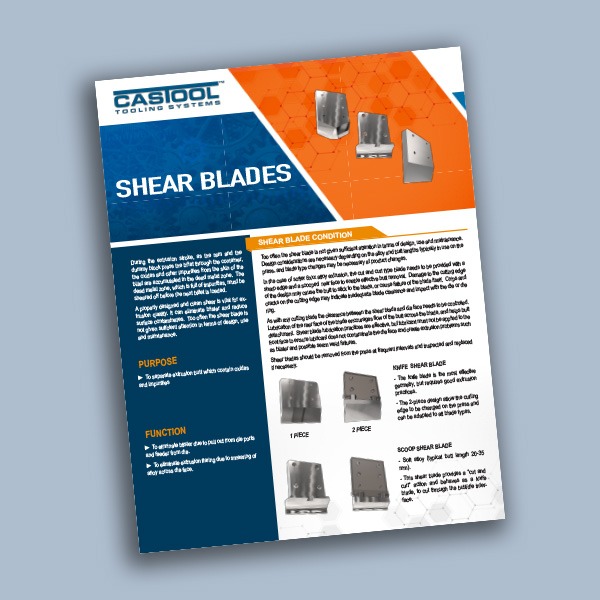

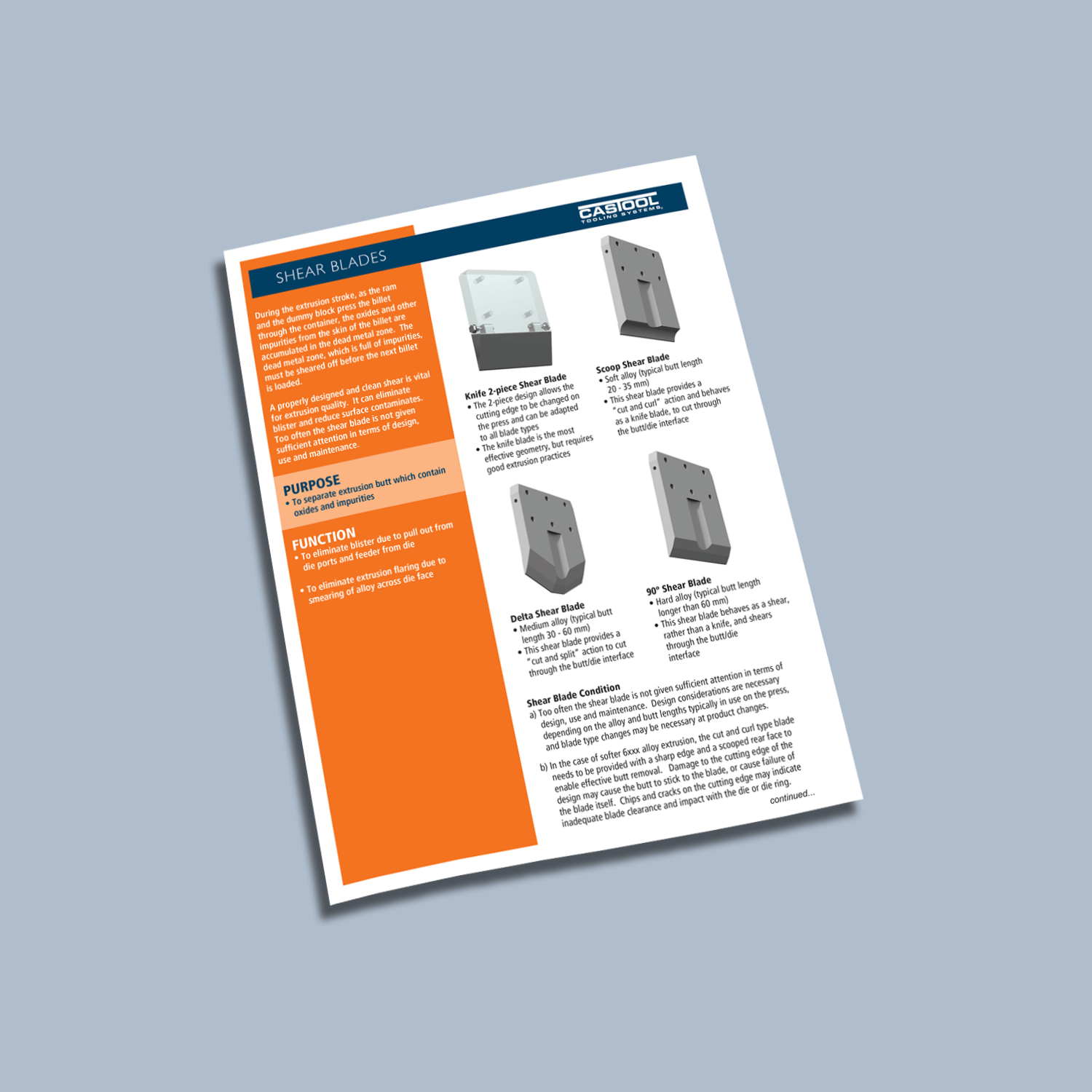

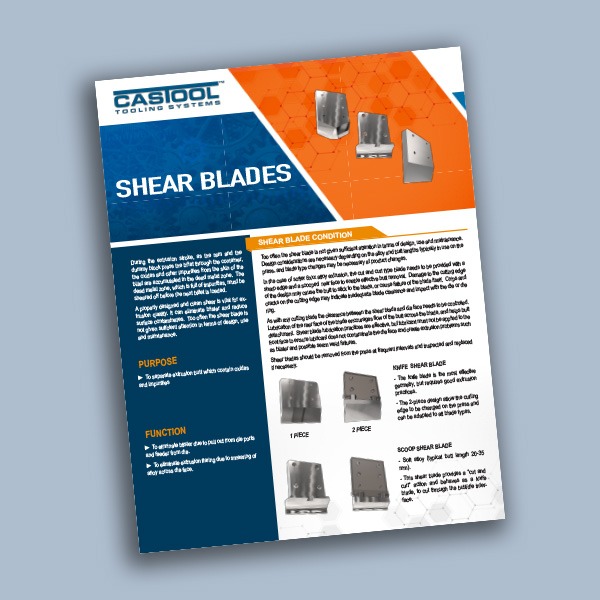

Shear Blades

Remote Optical Pyrometers

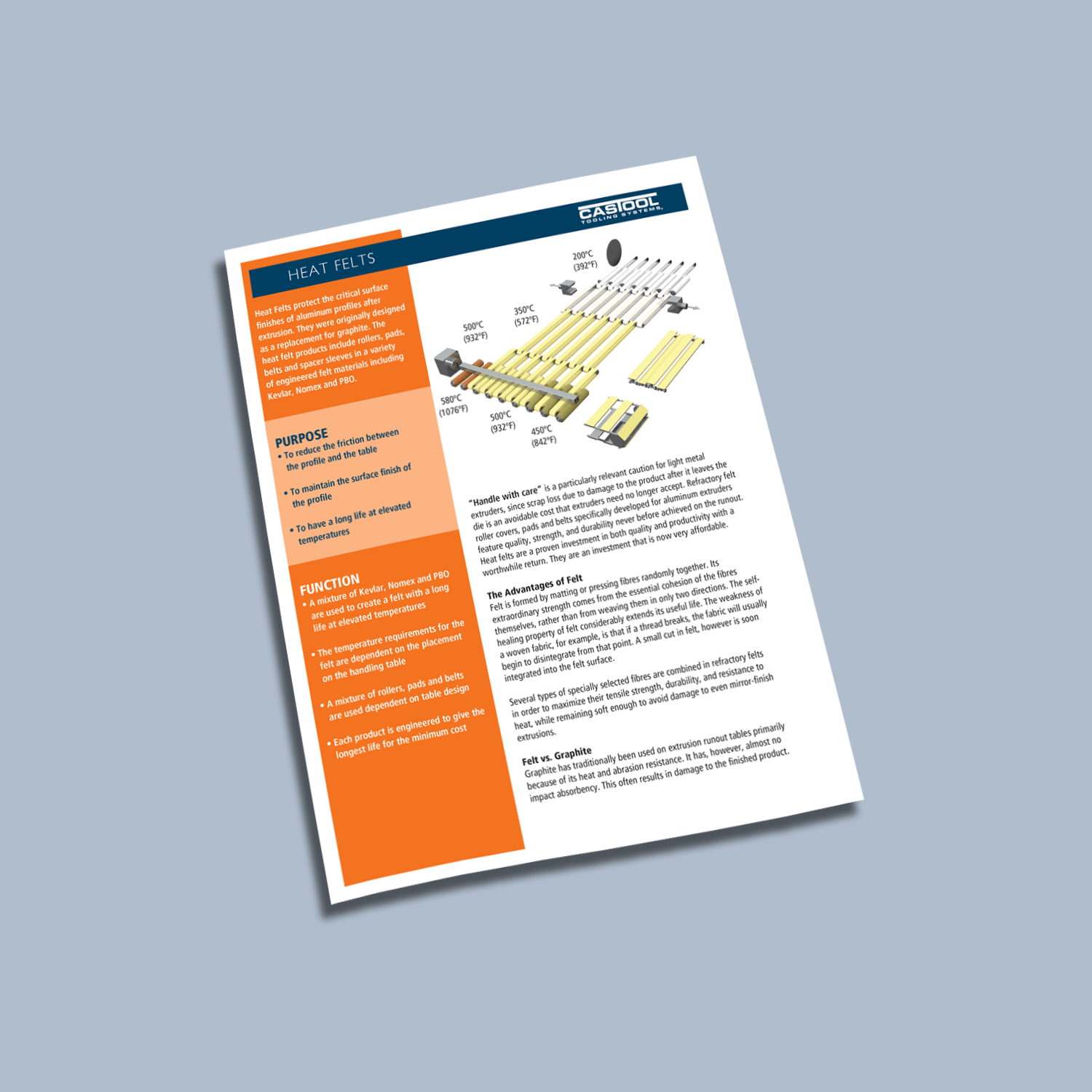

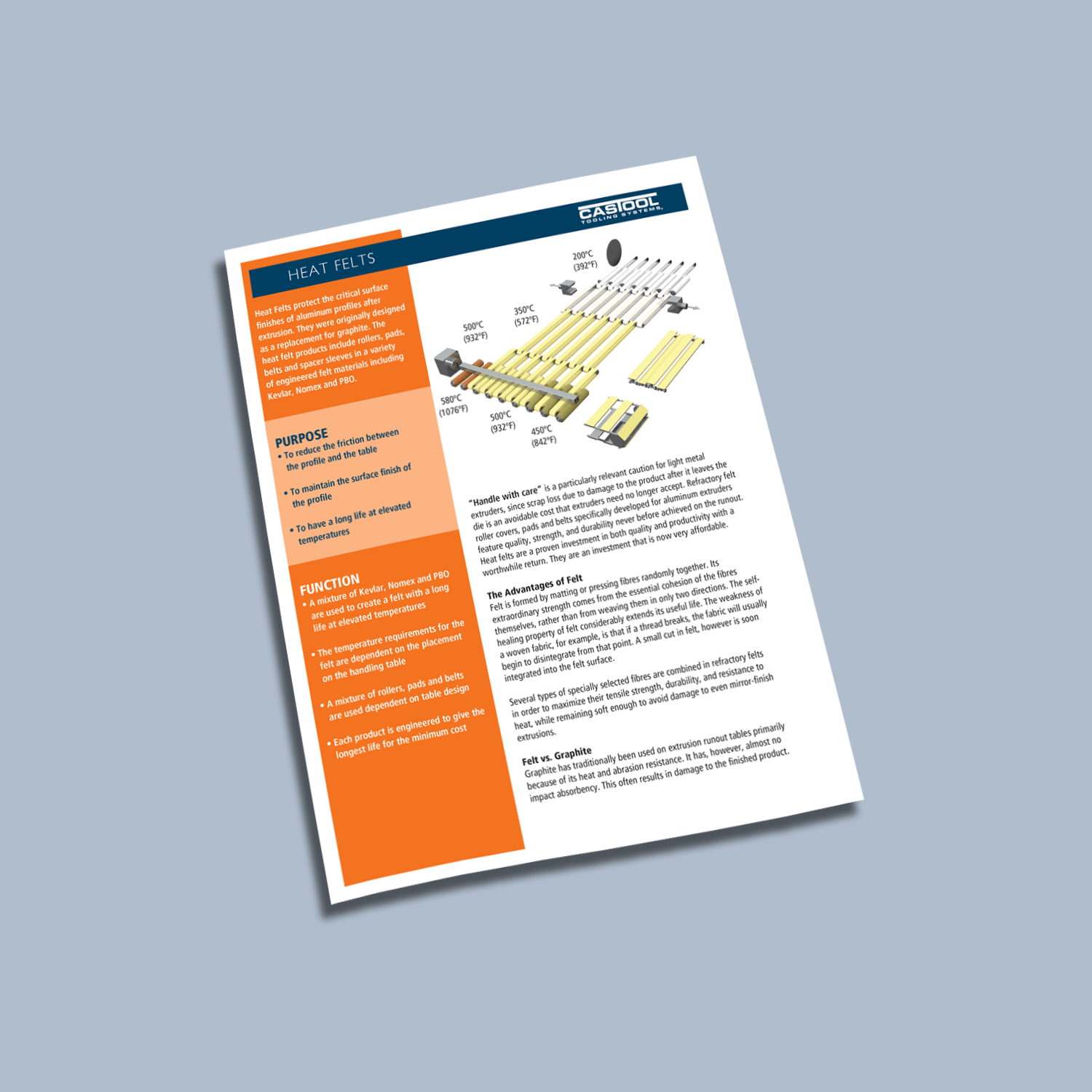

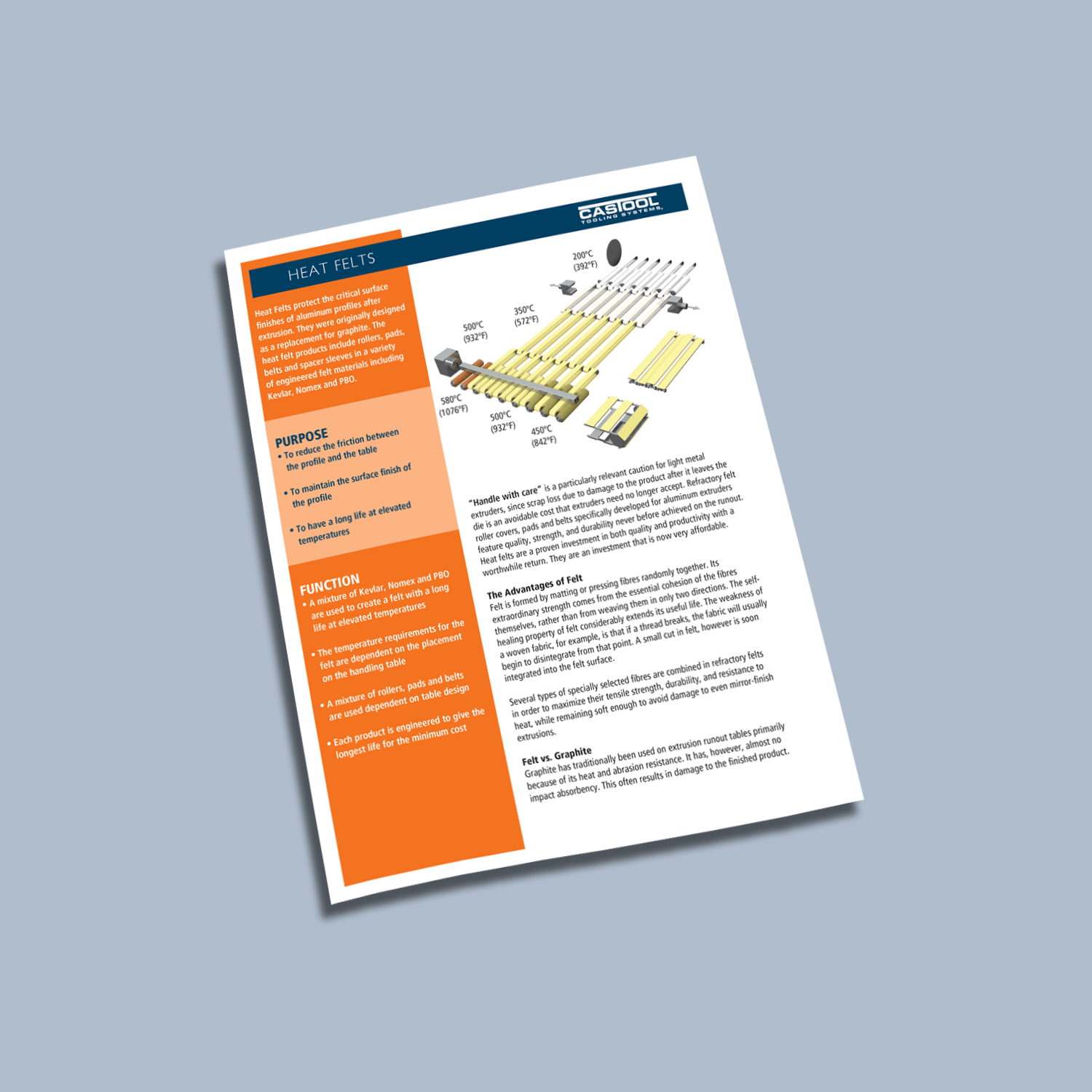

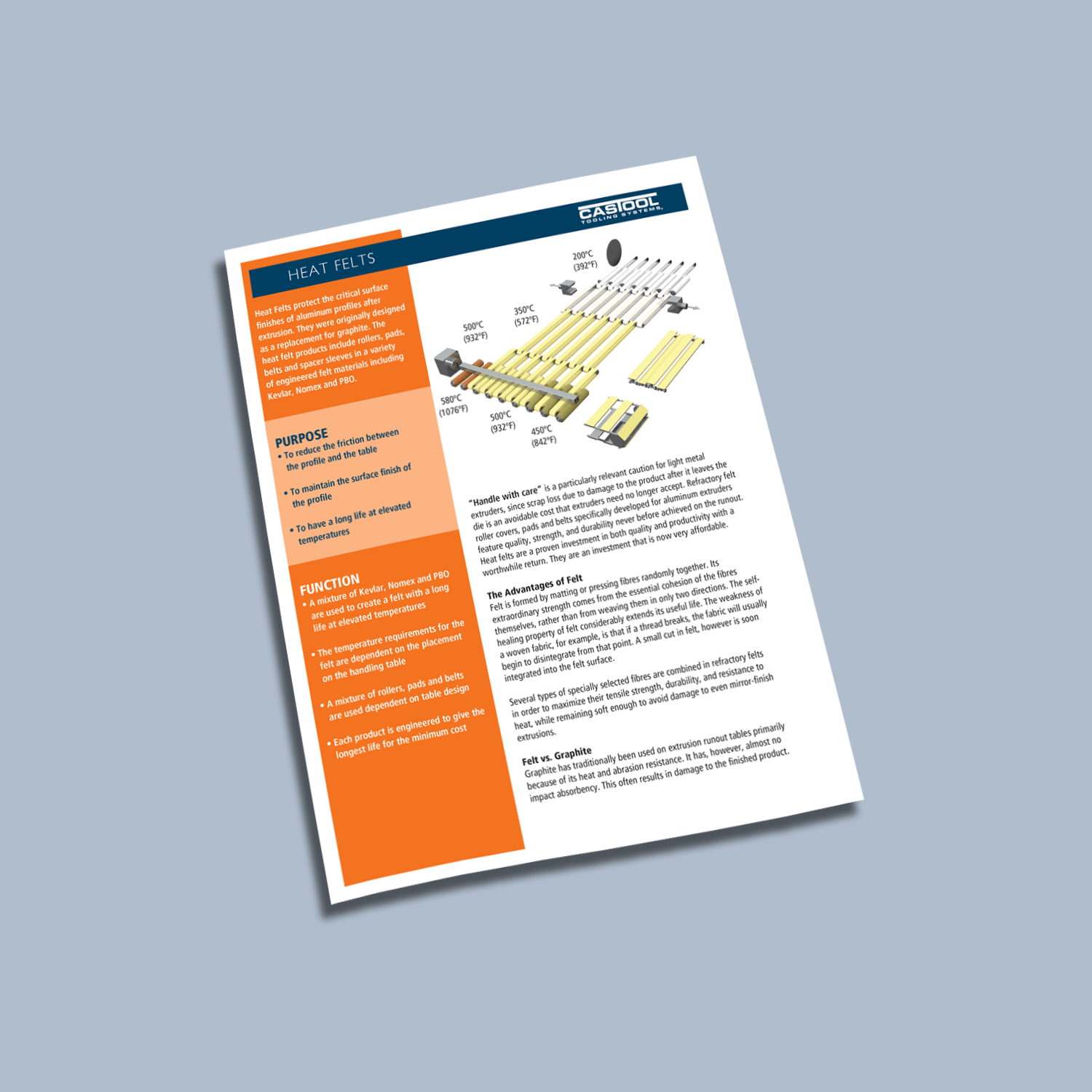

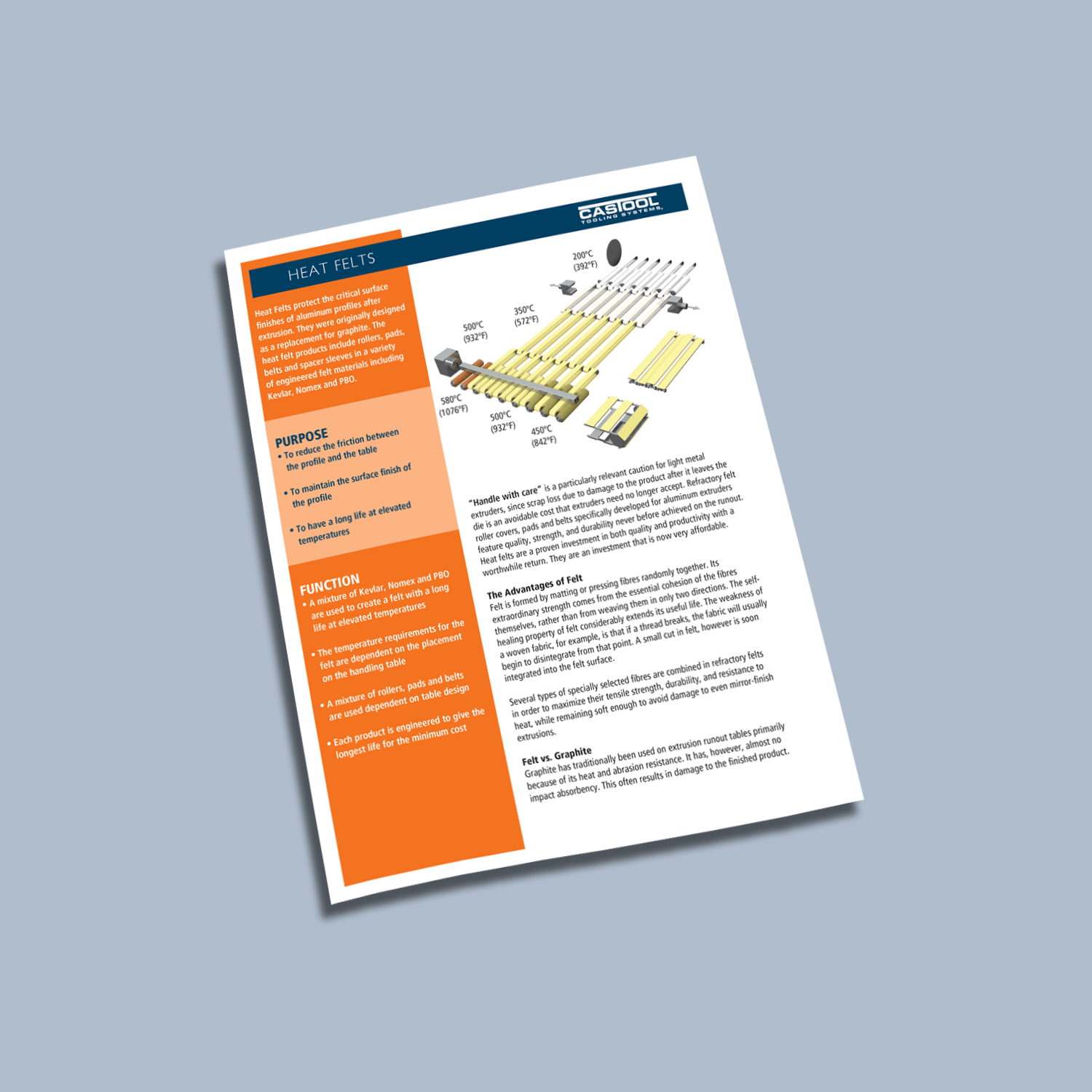

Heat Felts

Lubrication Extrusion

Die Ovens

Dummy Blocks

QR Containers

Clean out Block

CTS Vacuum VALVES

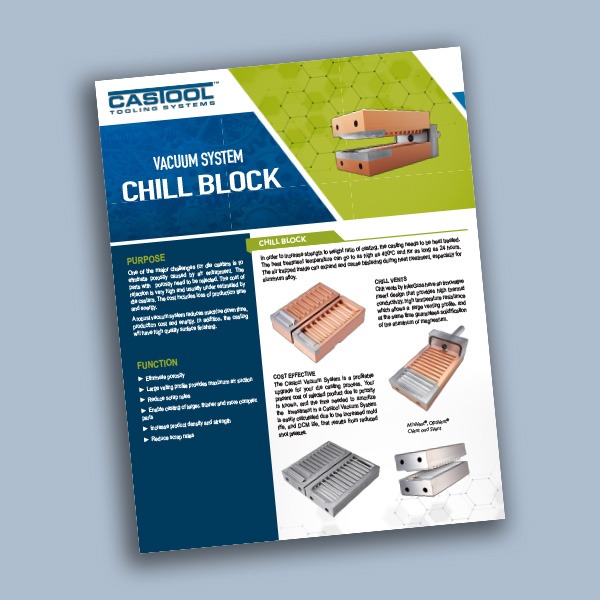

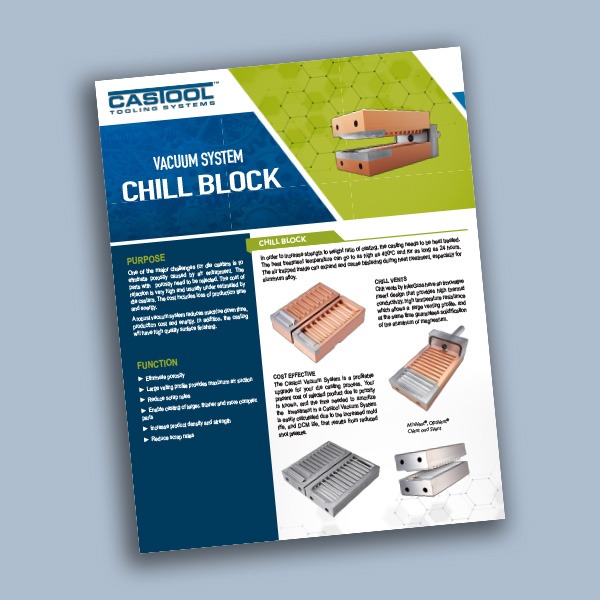

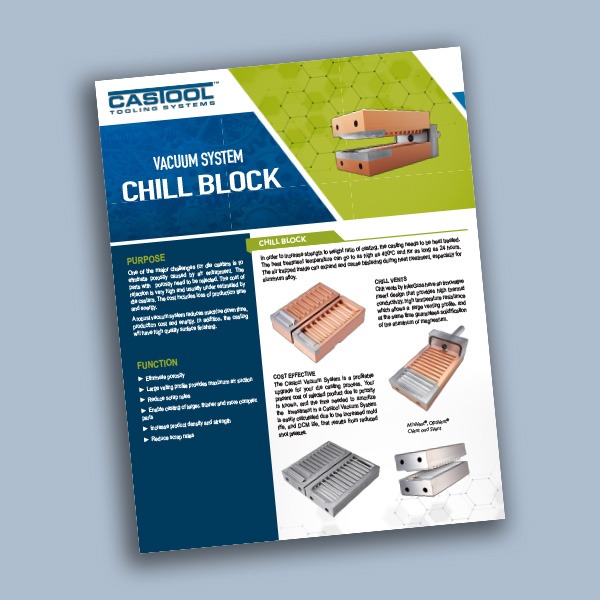

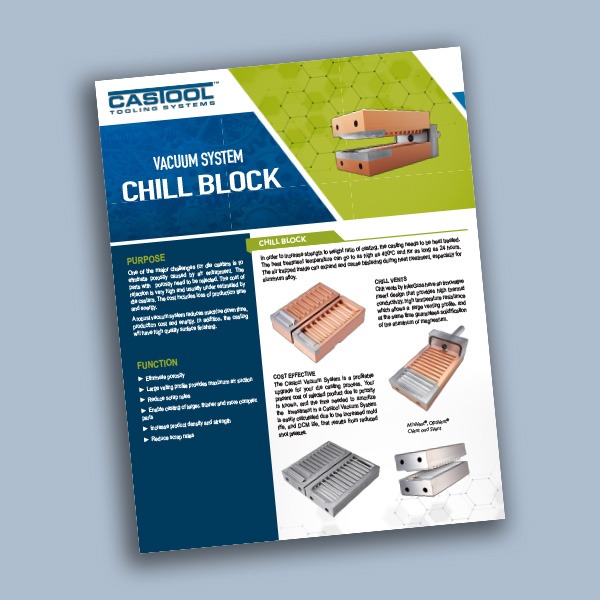

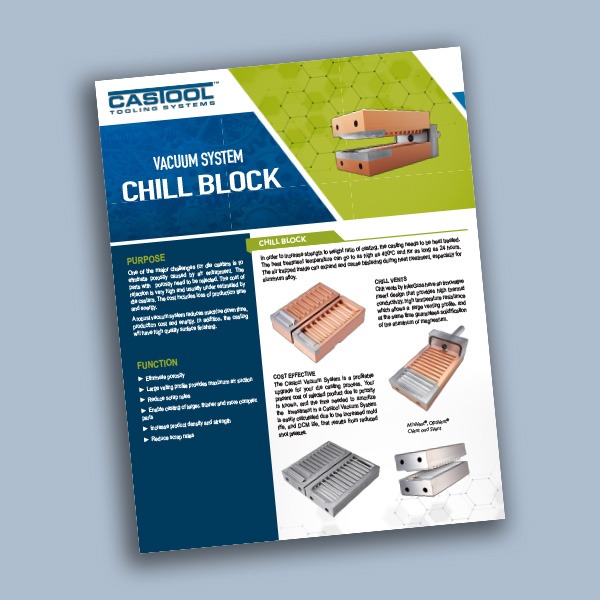

Vacuum Chill Block

Shot Sleeves

Plunger Tips AMP

Plunger Tips ABP

Lubrication Die Casting

Bore Welding

Personal Protective Equipment Policy

QMS Policy Manual – ISO 9001-2008 – 0514 Castool 180-16

OHSAS 18001 2007

ISO 9001-2015

ISO 14001 2015

QMS-0791-1

ISO 9001-2015

ISO 18001-2007

ISO 14001-2015

Workplace Violence Prevention Policy

Workplace Harassment Policy

SWP 23 Emergency Evacuation Plan

SWP 22 Emergency Evacuation Procedures

SWP 21 Emergency Medical Procedures

Lock Out Procedure

Customer Service Policy

Alcohol and Drug Abuse policy

Accessibility policy

Vacuum Assisted Die Casting

Plunger Design Meets Caster Requirements

A Time of Unmatched Opportunity

Its a Great Time to Be An Extruder

Billet Geometry

A Time of Unmatched Opportunity

The Single Cell Die Oven

The Fixed Dummy Block

Improve Measurement Improve Productivity

Bigger Castings – Bigger Problems

Benchmarking

Plunger Tip Design – Materials 07

ISO 45001 2018

Extrusion Productivity Part I – Billet Geometry

CTS Insider – Fall 2017

CTS Insider – Spring 2017

Health and Safety policy 2017

Improved Lubrication

Aluject offers better extrusion lubrication

Tooling System for Precision Tubing – Japanese

Plunger Design Excels in Cast Requirements

Injection System for Silafont

Tooling System for Precision Tubing

Dummy Block redefined for precision tubing

Thermally Stable Container

Dummy Block Paper

Container and DBlock interaction

Critical Interaction – DBlock Container

Plunger System for Silafont

High Pressure Die Casting Structural Aluminum

Container – Thermal Stability

The Black & White of Automotive Die Casting

Recycle AS a Last Resort

QR Container Manages the Die

The Black & White of Automotive Die Casting – Japanese

Extrusion Review since ET 2008

Extrusion as a Maturing Industry

Advanced Die Cast Tooling System

Ultimate Extrusion Tooling Systems

Better Interaction Key to Better Die Casting – Japanese

Die Heating Program

A Day in the Life

Time is Now for Vacuum Assisted Die Casting

Optimizing a Contemporary Extrusion Production System

Extrusion Today in NA

Extruding in a reset market

Complete Tool Package

Castool Alubin Israel Grant

Die Evacuation

You Need To Do Everything Durham Times 2008

Where Is The Extruder?

Opportunity in a Time of Change

Isothermal Extrusion Letter

Die Function

Die Function – Japanese

Better Interaction Key to Better Die Casting

Myth of the Perfect Die – Japanese

Extrusion Trends in NA – Chinese

Plunger Design 111th Metalcasting

10 Worst Practices by Light Metal Die Casters

Major Advance in Extrusion Die Temperature Control

Good Maintenance not Enough

Top 10 Worst Extrusion Practicies

The Value of Thermal And Physical Alignment

The Systems Approach

Extrusion A Major Change in Focus

Vacuum Assisted Casting

Industry Leader

The Castool Story

Precise Alignment is Key

Thermal Control of the Extrusion Press Container

The Systems Approach

The Maintenance of Extrusion Presses

The Castool Story

The Efficient Application of Die Lubricant

Factors increasing profits from short runs

That Fateful Four Thou (Die Casting Eng Set 2002)

Bigger Castings – Bigger Problems

Who Are The Superextruders

CTS Shear Blades

CTS ISO 45001 2018 – New

CTS Insider – Fall 2018

POCKET BROCHURE – DIE CASTING

POCKET BROCHURE – EXTRUSION

POCKET BROCHURE – TOOLING

Heat Treatment

The Difference Between Excellence and Mediocrity

Bigger Castings, Bigger Problems: Using Giga Presses to Cast Massive Automotive Parts

Contractor Handbook

Health and Safety Policy

A1.01 Castool IMS Policy 2023

SWP 21 Emergency Response Plan

December 2022 Newsletter

Die Casting Engineer – Bigger Castings Bigger Problems

Extrusion Productivity: Ram Speed/Die Design/Container

Plunger Tip Evolution in the Diecast Industry

Better Profiles Faster: Material Selection for Extrusion Tooling

Material Selection for Extrusion Containers

Material Selection for Extrusion Tooling – Part III

Better Castings Faster: Tooling Material, Process and Failure Analysis in Diecasting

Material Selection for Diecast Tooling: Decision Theory and Practice

Extrusion Productivity: Billet Geometry/Container/Dummy Block

Better Profiles Faster: Material Selection for Extrusion Tooling

A Fine Balance: The Difference between Excellence and Mediocrity

May 2022 Die Casting Engineer

CTS Insider – March 2022

Foundry

Billet Geometry – Japanese

Additive Manufacturing

Pressure and Leak Testing

Patents Die Cast

Visual Optimization System

Patents Extrusion

Tooling

Materials

Laboratory

CTS Insider – March 2021

Castool Laboratory

Castool Ring Plunger – CRP – Plunger Tips

Lubricants Liquid CLS200

Plunger Tips CRP

Alu Ject

CTS Insider – Summer 2020

CTS Insider – Spring 2020

CTS Insider – Winter 2020

ISO 14001 2015-Environmental

ISO 9001 2015-Quality

CTS Insider – Summer 2020

CTS Insider – Spring 2020

Fine Balance – The difference between excellence and mediocrity (Japanese)

Plunger Tips

Plunger Tips ARP

Extrusion Productivity Part II – Predicting of Ram Speed (Japanese)

CTS Insider – Winter 2019

CTS Insider – Fall 2019

CTS Insider – Summer 2019

CTS Insider – Spring 2019

Extrusion Productivity Part II – Predicting of Ram Speed

CTS Insider – Fall 2018

CTS Insider – Summer 2018

CTS Insider – Spring 2018

CTS Insider – Winter 2018

The Realities of Being a Superextruder Today

Stems

Shear Blades

Remote Optical Pyrometers

Heat Felts

Lubrication Extrusion

Die Ovens

Dummy Blocks

QR Containers

Clean out Block

CTS Vacuum VALVES

Vacuum Chill Block

Shot Sleeves

Plunger Tips AMP

Plunger Tips ABP

Lubrication Die Casting

Bore Welding

Personal Protective Equipment Policy

QMS Policy Manual – ISO 9001-2008 – 0514 Castool 180-16

OHSAS 18001 2007

ISO 9001-2015

ISO 14001 2015

QMS-0791-1

ISO 9001-2015

ISO 18001-2007

ISO 14001-2015

Workplace Violence Prevention Policy

Workplace Harassment Policy

SWP 23 Emergency Evacuation Plan

SWP 22 Emergency Evacuation Procedures

SWP 21 Emergency Medical Procedures

Lock Out Procedure

Customer Service Policy

Alcohol and Drug Abuse policy

Accessibility policy

Vacuum Assisted Die Casting

Plunger Design Meets Caster Requirements

A Time of Unmatched Opportunity

Its a Great Time to Be An Extruder

Billet Geometry

A Time of Unmatched Opportunity

The Single Cell Die Oven

The Fixed Dummy Block

Improve Measurement Improve Productivity

Bigger Castings – Bigger Problems

Benchmarking

Plunger Tip Design – Materials 07

ISO 45001 2018

Extrusion Productivity Part I – Billet Geometry

CTS Insider – Fall 2017

CTS Insider – Spring 2017

Health and Safety policy 2017

Improved Lubrication

Aluject offers better extrusion lubrication

Tooling System for Precision Tubing – Japanese

Plunger Design Excels in Cast Requirements

Injection System for Silafont

Tooling System for Precision Tubing

Dummy Block redefined for precision tubing

Thermally Stable Container

Dummy Block Paper

Container and DBlock interaction

Critical Interaction – DBlock Container

Plunger System for Silafont

High Pressure Die Casting Structural Aluminum

Container – Thermal Stability

The Black & White of Automotive Die Casting

Recycle AS a Last Resort

QR Container Manages the Die

The Black & White of Automotive Die Casting – Japanese

Extrusion Review since ET 2008

Extrusion as a Maturing Industry

Advanced Die Cast Tooling System

Ultimate Extrusion Tooling Systems

Better Interaction Key to Better Die Casting – Japanese

Die Heating Program

A Day in the Life

Time is Now for Vacuum Assisted Die Casting

Optimizing a Contemporary Extrusion Production System

Extrusion Today in NA

Extruding in a reset market

Complete Tool Package

Castool Alubin Israel Grant

Die Evacuation

You Need To Do Everything Durham Times 2008

Where Is The Extruder?

Opportunity in a Time of Change

Isothermal Extrusion Letter

Die Function

Die Function – Japanese

Better Interaction Key to Better Die Casting

Myth of the Perfect Die – Japanese

Extrusion Trends in NA – Chinese

Plunger Design 111th Metalcasting

10 Worst Practices by Light Metal Die Casters

Major Advance in Extrusion Die Temperature Control

Good Maintenance not Enough

Top 10 Worst Extrusion Practicies

The Value of Thermal And Physical Alignment

The Systems Approach

Extrusion A Major Change in Focus

Vacuum Assisted Casting

Industry Leader

The Castool Story

Precise Alignment is Key

Thermal Control of the Extrusion Press Container

The Systems Approach

The Maintenance of Extrusion Presses

The Castool Story

The Efficient Application of Die Lubricant

Factors increasing profits from short runs

That Fateful Four Thou (Die Casting Eng Set 2002)

Bigger Castings – Bigger Problems

Who Are The Superextruders

CTS Shear Blades

CTS ISO 45001 2018 – New

CTS Insider – Fall 2018

POCKET BROCHURE – DIE CASTING

POCKET BROCHURE – EXTRUSION

POCKET BROCHURE – TOOLING

Heat Treatment

The Difference Between Excellence and Mediocrity

Bigger Castings, Bigger Problems: Using Giga Presses to Cast Massive Automotive Parts

Contractor Handbook

Health and Safety Policy

A1.01 Castool IMS Policy 2023

SWP 21 Emergency Response Plan

December 2022 Newsletter

Die Casting Engineer – Bigger Castings Bigger Problems

Extrusion Productivity: Ram Speed/Die Design/Container

Plunger Tip Evolution in the Diecast Industry

Better Profiles Faster: Material Selection for Extrusion Tooling

Material Selection for Extrusion Containers

Material Selection for Extrusion Tooling – Part III

Better Castings Faster: Tooling Material, Process and Failure Analysis in Diecasting

Material Selection for Diecast Tooling: Decision Theory and Practice

Extrusion Productivity: Billet Geometry/Container/Dummy Block

Better Profiles Faster: Material Selection for Extrusion Tooling

A Fine Balance: The Difference between Excellence and Mediocrity

May 2022 Die Casting Engineer

CTS Insider – March 2022

Foundry

Billet Geometry – Japanese

Additive Manufacturing

Pressure and Leak Testing

Patents Die Cast

Visual Optimization System

Patents Extrusion

Tooling

Materials

Laboratory

CTS Insider – March 2021

Castool Laboratory

Castool Ring Plunger – CRP – Plunger Tips

Lubricants Liquid CLS200

Plunger Tips CRP

Alu Ject

CTS Insider – Summer 2020

CTS Insider – Spring 2020

CTS Insider – Winter 2020

ISO 14001 2015-Environmental

ISO 9001 2015-Quality

CTS Insider – Summer 2020

CTS Insider – Spring 2020

Fine Balance – The difference between excellence and mediocrity (Japanese)

Plunger Tips

Plunger Tips ARP

Extrusion Productivity Part II – Predicting of Ram Speed (Japanese)

CTS Insider – Winter 2019

CTS Insider – Fall 2019

CTS Insider – Summer 2019

CTS Insider – Spring 2019

Extrusion Productivity Part II – Predicting of Ram Speed

CTS Insider – Fall 2018

CTS Insider – Summer 2018

CTS Insider – Spring 2018

CTS Insider – Winter 2018

The Realities of Being a Superextruder Today

Stems

Shear Blades

Remote Optical Pyrometers

Heat Felts

Lubrication Extrusion

Die Ovens

Dummy Blocks

QR Containers

Clean out Block

CTS Vacuum VALVES

Vacuum Chill Block

Shot Sleeves

Plunger Tips AMP

Plunger Tips ABP

Lubrication Die Casting

Bore Welding

Personal Protective Equipment Policy

QMS Policy Manual – ISO 9001-2008 – 0514 Castool 180-16

OHSAS 18001 2007

ISO 9001-2015

ISO 14001 2015

QMS-0791-1

ISO 9001-2015

ISO 18001-2007

ISO 14001-2015

Workplace Violence Prevention Policy

Workplace Harassment Policy

SWP 23 Emergency Evacuation Plan

SWP 22 Emergency Evacuation Procedures

SWP 21 Emergency Medical Procedures

Lock Out Procedure

Customer Service Policy

Alcohol and Drug Abuse policy

Accessibility policy

Vacuum Assisted Die Casting

Plunger Design Meets Caster Requirements

A Time of Unmatched Opportunity

Its a Great Time to Be An Extruder

Billet Geometry

A Time of Unmatched Opportunity

The Single Cell Die Oven

The Fixed Dummy Block

Improve Measurement Improve Productivity

Bigger Castings – Bigger Problems

Benchmarking

Plunger Tip Design – Materials 07

ISO 45001 2018

Extrusion Productivity Part I – Billet Geometry

CTS Insider – Fall 2017

CTS Insider – Spring 2017

Health and Safety policy 2017

Improved Lubrication

Aluject offers better extrusion lubrication

Tooling System for Precision Tubing – Japanese

Plunger Design Excels in Cast Requirements

Injection System for Silafont

Tooling System for Precision Tubing

Dummy Block redefined for precision tubing

Thermally Stable Container

Dummy Block Paper

Container and DBlock interaction

Critical Interaction – DBlock Container

Plunger System for Silafont

High Pressure Die Casting Structural Aluminum

Container – Thermal Stability

The Black & White of Automotive Die Casting

Recycle AS a Last Resort

QR Container Manages the Die

The Black & White of Automotive Die Casting – Japanese

Extrusion Review since ET 2008

Extrusion as a Maturing Industry

Advanced Die Cast Tooling System

Ultimate Extrusion Tooling Systems

Better Interaction Key to Better Die Casting – Japanese

Die Heating Program

A Day in the Life

Time is Now for Vacuum Assisted Die Casting

Optimizing a Contemporary Extrusion Production System

Extrusion Today in NA

Extruding in a reset market

Complete Tool Package

Castool Alubin Israel Grant

Die Evacuation

You Need To Do Everything Durham Times 2008

Where Is The Extruder?

Opportunity in a Time of Change

Isothermal Extrusion Letter

Die Function

Die Function – Japanese

Better Interaction Key to Better Die Casting

Myth of the Perfect Die – Japanese

Extrusion Trends in NA – Chinese

Plunger Design 111th Metalcasting

10 Worst Practices by Light Metal Die Casters

Major Advance in Extrusion Die Temperature Control

Good Maintenance not Enough

Top 10 Worst Extrusion Practicies

The Value of Thermal And Physical Alignment

The Systems Approach

Extrusion A Major Change in Focus

Vacuum Assisted Casting

Industry Leader

The Castool Story

Precise Alignment is Key

Thermal Control of the Extrusion Press Container

The Systems Approach

The Maintenance of Extrusion Presses

The Castool Story

The Efficient Application of Die Lubricant

Factors increasing profits from short runs

That Fateful Four Thou (Die Casting Eng Set 2002)

Bigger Castings – Bigger Problems

Who Are The Superextruders

CTS Shear Blades

CTS ISO 45001 2018 – New

CTS Insider – Fall 2018

POCKET BROCHURE – DIE CASTING

POCKET BROCHURE – EXTRUSION

POCKET BROCHURE – TOOLING

Heat Treatment

The Difference Between Excellence and Mediocrity

Bigger Castings, Bigger Problems: Using Giga Presses to Cast Massive Automotive Parts

Contractor Handbook

Health and Safety Policy

A1.01 Castool IMS Policy 2023

SWP 21 Emergency Response Plan

December 2022 Newsletter

Die Casting Engineer – Bigger Castings Bigger Problems

Extrusion Productivity: Ram Speed/Die Design/Container

Plunger Tip Evolution in the Diecast Industry

Better Profiles Faster: Material Selection for Extrusion Tooling

Material Selection for Extrusion Containers

Material Selection for Extrusion Tooling – Part III

Better Castings Faster: Tooling Material, Process and Failure Analysis in Diecasting

Material Selection for Diecast Tooling: Decision Theory and Practice

Extrusion Productivity: Billet Geometry/Container/Dummy Block

Better Profiles Faster: Material Selection for Extrusion Tooling

A Fine Balance: The Difference between Excellence and Mediocrity

May 2022 Die Casting Engineer

CTS Insider – March 2022

Foundry

Billet Geometry – Japanese

Additive Manufacturing

Pressure and Leak Testing

Patents Die Cast

Visual Optimization System

Patents Extrusion

Tooling

Materials

Laboratory

CTS Insider – March 2021

Castool Laboratory

Castool Ring Plunger – CRP – Plunger Tips

Lubricants Liquid CLS200

Plunger Tips CRP

Alu Ject

CTS Insider – Summer 2020

CTS Insider – Spring 2020

CTS Insider – Winter 2020

ISO 14001 2015-Environmental

ISO 9001 2015-Quality

CTS Insider – Summer 2020

CTS Insider – Spring 2020

Fine Balance – The difference between excellence and mediocrity (Japanese)

Plunger Tips

Plunger Tips ARP

Extrusion Productivity Part II – Predicting of Ram Speed (Japanese)

CTS Insider – Winter 2019

CTS Insider – Fall 2019

CTS Insider – Summer 2019

CTS Insider – Spring 2019

Extrusion Productivity Part II – Predicting of Ram Speed

CTS Insider – Fall 2018

CTS Insider – Summer 2018

CTS Insider – Spring 2018

CTS Insider – Winter 2018

The Realities of Being a Superextruder Today

Stems

Shear Blades

Remote Optical Pyrometers

Heat Felts

Lubrication Extrusion

Die Ovens

Dummy Blocks

QR Containers

Clean out Block

CTS Vacuum VALVES

Vacuum Chill Block

Shot Sleeves

Plunger Tips AMP

Plunger Tips ABP

Lubrication Die Casting

Bore Welding

Personal Protective Equipment Policy

QMS Policy Manual – ISO 9001-2008 – 0514 Castool 180-16

OHSAS 18001 2007

ISO 9001-2015

ISO 14001 2015

QMS-0791-1

ISO 9001-2015

ISO 18001-2007

ISO 14001-2015

Workplace Violence Prevention Policy

Workplace Harassment Policy

SWP 23 Emergency Evacuation Plan

SWP 22 Emergency Evacuation Procedures

SWP 21 Emergency Medical Procedures

Lock Out Procedure

Customer Service Policy

Alcohol and Drug Abuse policy

Accessibility policy

Vacuum Assisted Die Casting

Plunger Design Meets Caster Requirements

A Time of Unmatched Opportunity

Its a Great Time to Be An Extruder

Billet Geometry

A Time of Unmatched Opportunity

The Single Cell Die Oven

The Fixed Dummy Block

Improve Measurement Improve Productivity

Bigger Castings – Bigger Problems

Benchmarking

Plunger Tip Design – Materials 07

ISO 45001 2018

Extrusion Productivity Part I – Billet Geometry

CTS Insider – Fall 2017

CTS Insider – Spring 2017

Health and Safety policy 2017

Improved Lubrication

Aluject offers better extrusion lubrication

Tooling System for Precision Tubing – Japanese

Plunger Design Excels in Cast Requirements

Injection System for Silafont

Tooling System for Precision Tubing

Dummy Block redefined for precision tubing

Thermally Stable Container

Dummy Block Paper

Container and DBlock interaction

Critical Interaction – DBlock Container

Plunger System for Silafont

High Pressure Die Casting Structural Aluminum

Container – Thermal Stability

The Black & White of Automotive Die Casting

Recycle AS a Last Resort

QR Container Manages the Die

The Black & White of Automotive Die Casting – Japanese

Extrusion Review since ET 2008

Extrusion as a Maturing Industry

Advanced Die Cast Tooling System

Ultimate Extrusion Tooling Systems

Better Interaction Key to Better Die Casting – Japanese

Die Heating Program

A Day in the Life

Time is Now for Vacuum Assisted Die Casting

Optimizing a Contemporary Extrusion Production System

Extrusion Today in NA

Extruding in a reset market

Complete Tool Package

Castool Alubin Israel Grant

Die Evacuation

You Need To Do Everything Durham Times 2008

Where Is The Extruder?

Opportunity in a Time of Change

Isothermal Extrusion Letter

Die Function

Die Function – Japanese

Better Interaction Key to Better Die Casting

Myth of the Perfect Die – Japanese

Extrusion Trends in NA – Chinese

Plunger Design 111th Metalcasting

10 Worst Practices by Light Metal Die Casters

Major Advance in Extrusion Die Temperature Control

Good Maintenance not Enough

Top 10 Worst Extrusion Practicies

The Value of Thermal And Physical Alignment

The Systems Approach

Extrusion A Major Change in Focus

Vacuum Assisted Casting

Industry Leader

The Castool Story

Precise Alignment is Key

Thermal Control of the Extrusion Press Container

The Systems Approach

The Maintenance of Extrusion Presses

The Castool Story

The Efficient Application of Die Lubricant

Factors increasing profits from short runs

That Fateful Four Thou (Die Casting Eng Set 2002)

Bigger Castings – Bigger Problems

Who Are The Superextruders

CTS Shear Blades

CTS ISO 45001 2018 – New

CTS Insider – Fall 2018

POCKET BROCHURE – DIE CASTING

POCKET BROCHURE – EXTRUSION

POCKET BROCHURE – TOOLING

Heat Treatment

The Difference Between Excellence and Mediocrity

Bigger Castings, Bigger Problems: Using Giga Presses to Cast Massive Automotive Parts

Contractor Handbook

Health and Safety Policy

A1.01 Castool IMS Policy 2023

SWP 21 Emergency Response Plan

December 2022 Newsletter

Die Casting Engineer – Bigger Castings Bigger Problems

Extrusion Productivity: Ram Speed/Die Design/Container

Plunger Tip Evolution in the Diecast Industry

Better Profiles Faster: Material Selection for Extrusion Tooling

Material Selection for Extrusion Containers

Material Selection for Extrusion Tooling – Part III

Better Castings Faster: Tooling Material, Process and Failure Analysis in Diecasting

Material Selection for Diecast Tooling: Decision Theory and Practice

Extrusion Productivity: Billet Geometry/Container/Dummy Block

Better Profiles Faster: Material Selection for Extrusion Tooling

A Fine Balance: The Difference between Excellence and Mediocrity

May 2022 Die Casting Engineer

CTS Insider – March 2022

Foundry

Billet Geometry – Japanese

Additive Manufacturing

Pressure and Leak Testing

Patents Die Cast

Visual Optimization System

Patents Extrusion

Tooling

Materials

Laboratory

CTS Insider – March 2021

Castool Laboratory

Castool Ring Plunger – CRP – Plunger Tips

Lubricants Liquid CLS200

Plunger Tips CRP

Alu Ject

CTS Insider – Summer 2020

CTS Insider – Spring 2020

CTS Insider – Winter 2020

ISO 14001 2015-Environmental

ISO 9001 2015-Quality

CTS Insider – Summer 2020

CTS Insider – Spring 2020

Fine Balance – The difference between excellence and mediocrity (Japanese)

Plunger Tips

Plunger Tips ARP

Extrusion Productivity Part II – Predicting of Ram Speed (Japanese)

CTS Insider – Winter 2019

CTS Insider – Fall 2019

CTS Insider – Summer 2019

CTS Insider – Spring 2019

Extrusion Productivity Part II – Predicting of Ram Speed

CTS Insider – Fall 2018

CTS Insider – Summer 2018

CTS Insider – Spring 2018

CTS Insider – Winter 2018

The Realities of Being a Superextruder Today

Stems

Shear Blades

Remote Optical Pyrometers

Heat Felts

Lubrication Extrusion

Die Ovens

Dummy Blocks

QR Containers

Clean out Block

CTS Vacuum VALVES

Vacuum Chill Block

Shot Sleeves

Plunger Tips AMP

Plunger Tips ABP

Lubrication Die Casting

Bore Welding

Personal Protective Equipment Policy

QMS Policy Manual – ISO 9001-2008 – 0514 Castool 180-16

OHSAS 18001 2007

ISO 9001-2015

ISO 14001 2015

QMS-0791-1

ISO 9001-2015

ISO 18001-2007

ISO 14001-2015

Workplace Violence Prevention Policy

Workplace Harassment Policy

SWP 23 Emergency Evacuation Plan

SWP 22 Emergency Evacuation Procedures

SWP 21 Emergency Medical Procedures

Lock Out Procedure

Customer Service Policy

Alcohol and Drug Abuse policy

Accessibility policy

Vacuum Assisted Die Casting

Plunger Design Meets Caster Requirements

A Time of Unmatched Opportunity

Its a Great Time to Be An Extruder

Billet Geometry

A Time of Unmatched Opportunity

The Single Cell Die Oven

The Fixed Dummy Block

Improve Measurement Improve Productivity

Bigger Castings – Bigger Problems

Benchmarking

Plunger Tip Design – Materials 07

ISO 45001 2018

Extrusion Productivity Part I – Billet Geometry

CTS Insider – Fall 2017

CTS Insider – Spring 2017

Health and Safety policy 2017

Improved Lubrication

Aluject offers better extrusion lubrication

Tooling System for Precision Tubing – Japanese

Plunger Design Excels in Cast Requirements

Injection System for Silafont

Tooling System for Precision Tubing

Dummy Block redefined for precision tubing

Thermally Stable Container

Dummy Block Paper

Container and DBlock interaction

Critical Interaction – DBlock Container

Plunger System for Silafont

High Pressure Die Casting Structural Aluminum

Container – Thermal Stability

The Black & White of Automotive Die Casting

Recycle AS a Last Resort

QR Container Manages the Die

The Black & White of Automotive Die Casting – Japanese

Extrusion Review since ET 2008

Extrusion as a Maturing Industry

Advanced Die Cast Tooling System

Ultimate Extrusion Tooling Systems

Better Interaction Key to Better Die Casting – Japanese

Die Heating Program

A Day in the Life

Time is Now for Vacuum Assisted Die Casting

Optimizing a Contemporary Extrusion Production System

Extrusion Today in NA

Extruding in a reset market

Complete Tool Package

Castool Alubin Israel Grant

Die Evacuation

You Need To Do Everything Durham Times 2008

Where Is The Extruder?

Opportunity in a Time of Change

Isothermal Extrusion Letter

Die Function

Die Function – Japanese

Better Interaction Key to Better Die Casting

Myth of the Perfect Die – Japanese

Extrusion Trends in NA – Chinese

Plunger Design 111th Metalcasting

10 Worst Practices by Light Metal Die Casters

Major Advance in Extrusion Die Temperature Control

Good Maintenance not Enough

Top 10 Worst Extrusion Practicies

The Value of Thermal And Physical Alignment

The Systems Approach

Extrusion A Major Change in Focus

Vacuum Assisted Casting

Industry Leader

The Castool Story

Precise Alignment is Key

Thermal Control of the Extrusion Press Container

The Systems Approach

The Maintenance of Extrusion Presses

The Castool Story

The Efficient Application of Die Lubricant

Factors increasing profits from short runs

That Fateful Four Thou (Die Casting Eng Set 2002)

Bigger Castings – Bigger Problems

Who Are The Superextruders