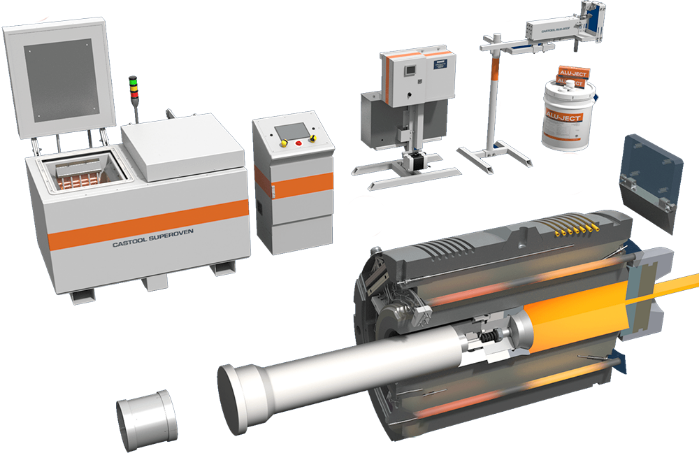

Extrusion

Better Profiles Faster

No single component of the extrusion production process should be examined or evaluated individually

Each interacts with at least one other complementary element of the process. If the interacting elements are equally efficient, they will reinforce and enhance the function for each other.

Only if the entire production process is considered as an integrated system, with all parts operating together in common cause, can maximum efficiency be approached.

Better Profiles Faster

Many of Castool products and processes are Patended.

Castool has done excellent work over the years and as a result of the superior quality and performance of our tools, we patented some of our outstanding works.