The dummy block is a critical element for extrusion quality and press performance. A dummy block is in direct contact with the billet. Therefore, its successful operation depends on several factors. The most important factor among them is its’ efficient interaction with a round, straight, thermally – and, therefore, dimensionally – stable container.

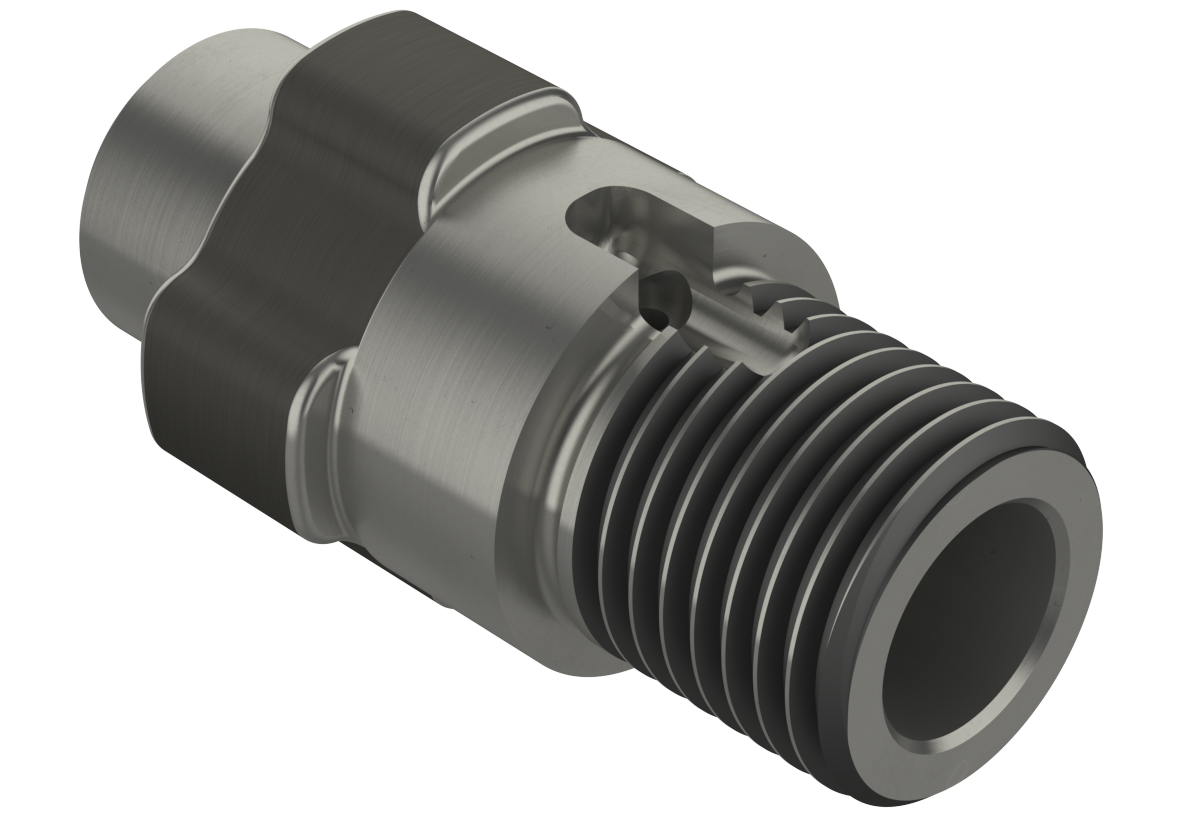

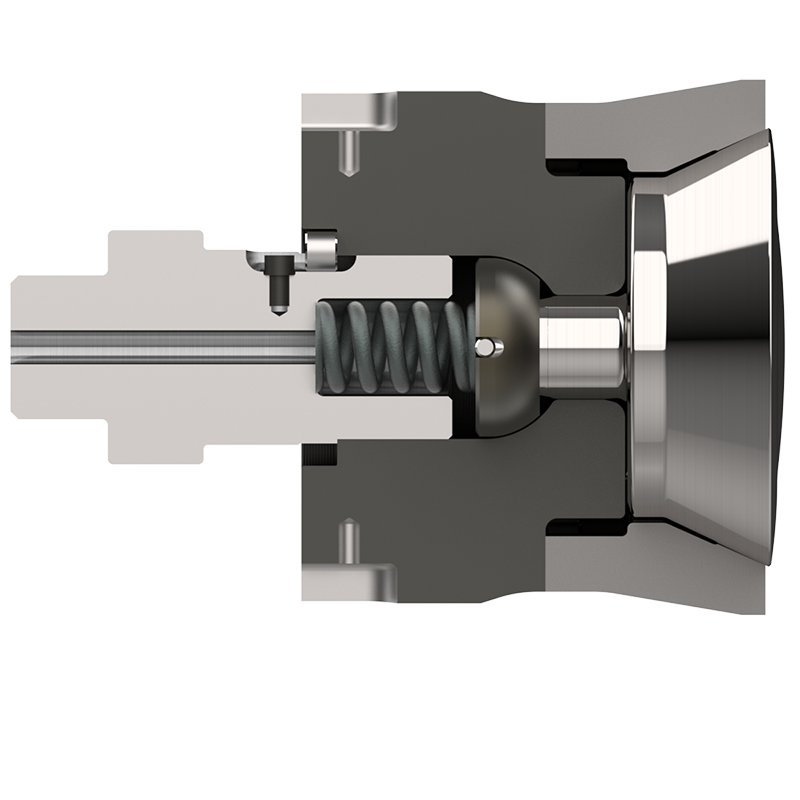

Castool uses a unique bayonet-type coupling which locks the dummy block quickly and securely to the stem. This makes it much easier and faster to replace a very hot block than with a conventional screw-type or rod coupling. Castool uses a secondary stabilizing stud (behind the bayonet), to limit the amount of lateral movement of the block on the stem. The stabilizing stud can reduce the lateral movement from 0.7 mm to 0.2 mm.

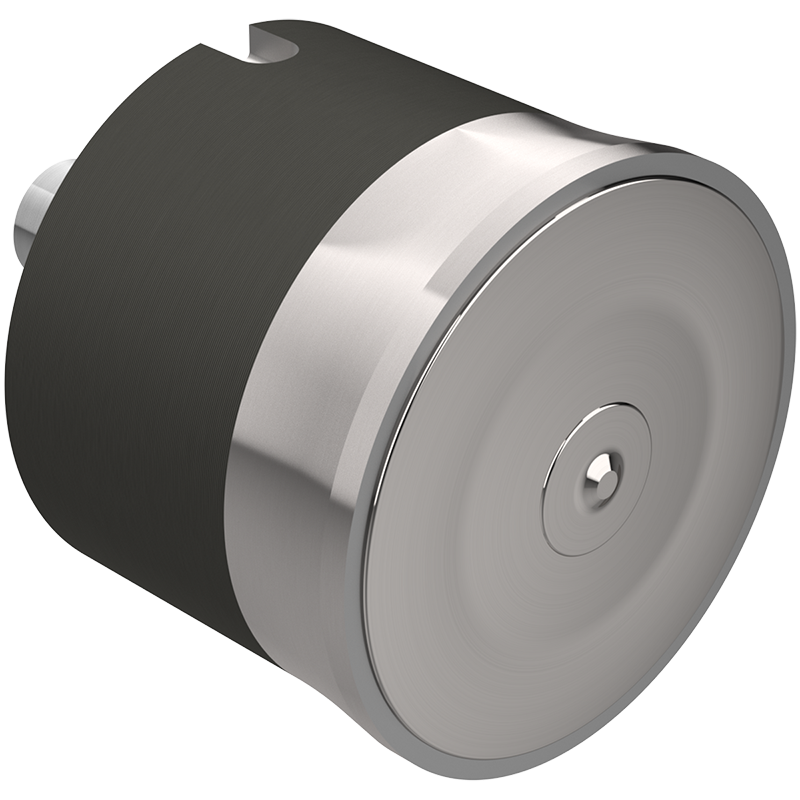

ADB – Apex Disc Block, is an evolution of the old favorite QEB, quick expansion block. The HPR has a similar expanding wear component. The full-length ring is relatively thin and of uniform thickness. It expands quickly, making it suitable for presses with rapid acceleration. The ring has an interference fit with the body or holder, which allows the pad to be very large. The large pad area reduces high pressure deformation.

Marathon – This extra strong 2-piece block emphasizes quality of product plus length of operating life. The sturdy design provides excellent long elasticity life and rigidity.

RRB – Replaceable Ring Block for standard long stroke presses up to 100,000 psi. The combinations of the ring hoop strength and the yield strength of the mandrel and holder have been carefully designed. The ring expands to pre-determined size at a pre-determined pressure. It provides long-lasting dummy block elastic expansion and contraction.

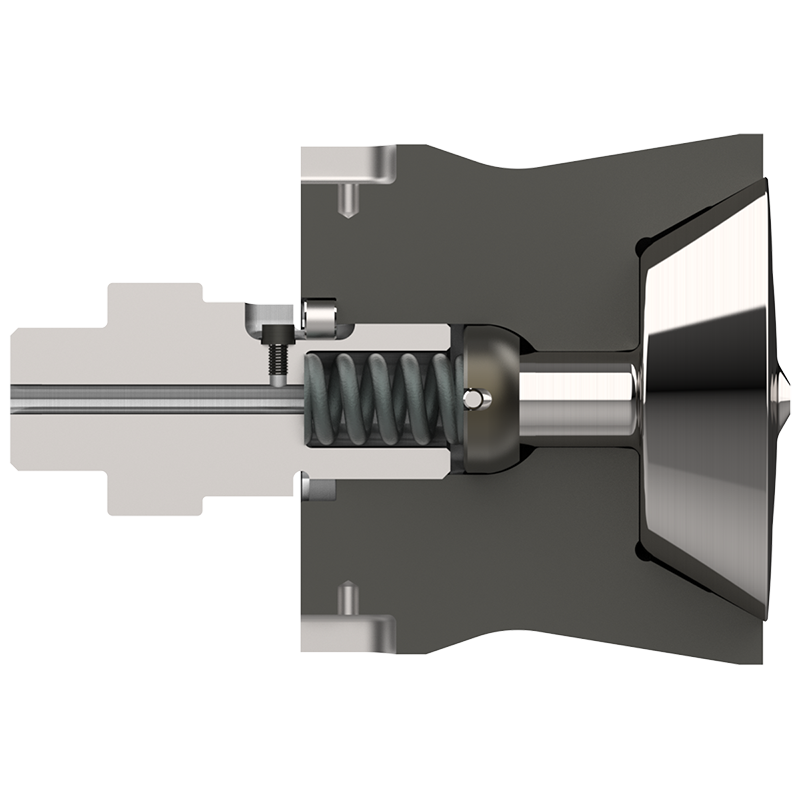

Purpose

- Allow gases to escape during the combined process of billet upset, and burp decompression, reducing blisters

- Maintain a minimal uniform skin of aluminum on the liner inner diameter reducing profile inclusions

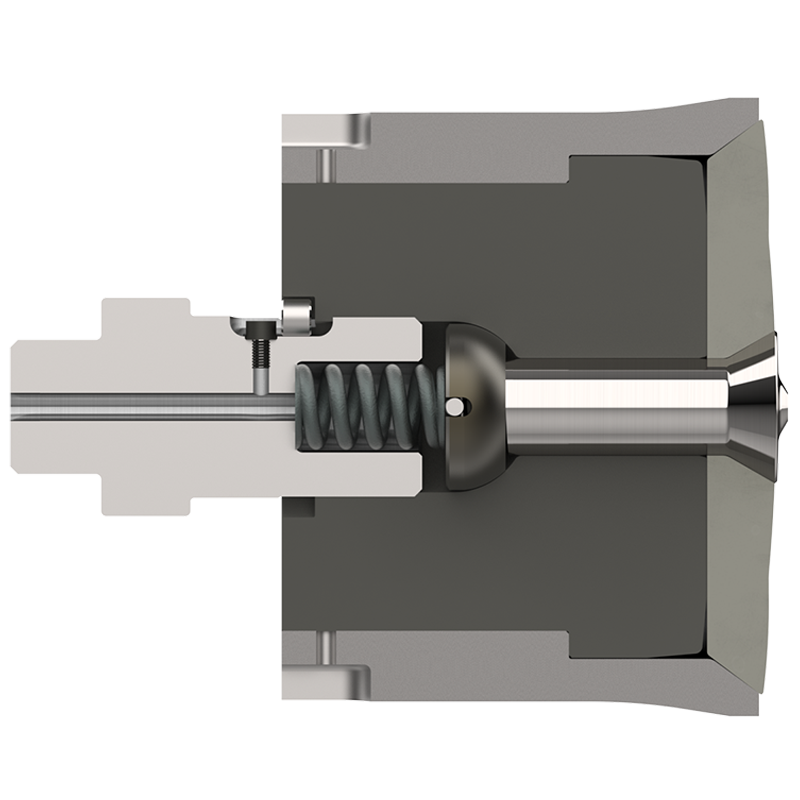

Function

- The function of the dummy block is the extension of the ram or stem, which pushes the softened alloy through the die. There are a number of functions that must be satisfied by an effective dummy block.

- To repeatedly transmit the force of the ram, at high temperature, to the alloy

- To expand to pre-determined size under load and maintain a secure seal with the container wall, leaving only a thin film of alloy on the liner

- To separate cleanly from the billet at the end of the stroke

- To contract immediately, and return through the container without stripping the film of alloy from the liner

- To cause no gas entrapment that can result in blistering, or damage the face of the container and/ or dummy block

- To compensate for minor press misalignment

- To be quickly and easily removed and replaced

- To function effectively until a production run is complete

- Reduce scrap, due to back end blisters and surface defects

- Reduce cost of operation

- Reduce downtime

- Increase productivity

- Increase operating life

- Increase container liner life