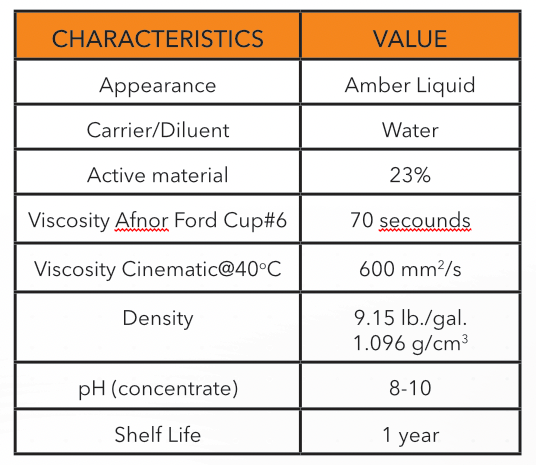

ALU-JECT is a non-pigmented, water based lubricant designed for billet end coating. It is formulated using organometallic compounds which apply a boundary film to prevent welding of the billet to the dummy block, providing excellent release characteristics.

Alu-Ject is a non-pigmented, water-based lubricant designed for billet end coating. The formula uses organometallic compounds which apply a boundary film to prevent welding of the billet to the dummy block, providing excellent release characteristics.

ALU-JECT is a soluble lubricant made up of a blend of acids and salts to form a soap. The lubricant dries onto the billet forming a lubricant barrier protecting the dummy block from the aluminum billet and allowing the dummy block to easily retract without any adhesion to the billet.

ALU-JECT is a non-pigmented, water based lubricant designed for billet and coating. It is formulated using organometallic compounds which apply a boundary film to prevent welding of the billet to the dummy block; providing excellent release characteristics. ALU-JECT is capable of wetting temperature as high as 1112º F (600º C).

Greases and oil-based graphite suspensions can only be applied by hand. They are cheap, but require a worker to be present at all times. These materials are inflammable at high temperature. This can cause problems with electrical equipment. Also explosions create blisters in the billet, which can lead to small holes in the extruded profile. This cannot be tolerated by most markets today. Handling is also messy, and the material is environmentally problematic.

Acetylene is ignited in front of the billet, generating carbon black. Acetylene was the first technology to operate automatically, since the flame is lit as the billet passes the burner on its way out of the preheating furnace. Carbon is a good release agent, but due to its small size, carbon black is a carcinogenic. Workers must be protected against breathing in any powder that does not stick to the billet. This also causes problems with the quality of the extruded profile. It can create black marks on the profile that cannot be removed and interfere with anodizing.

The application of electrostatic Boron Nitride (BN) is a good alternative. Its release and lubrication characteristics outperform carbon black. It is also simple to automate the coating of the billet when using BN. BN is not carcinogenic, is nontoxic and chemically inert. There will be no white marks, even inside the die, therefore there are no marks on the profile surfaces.

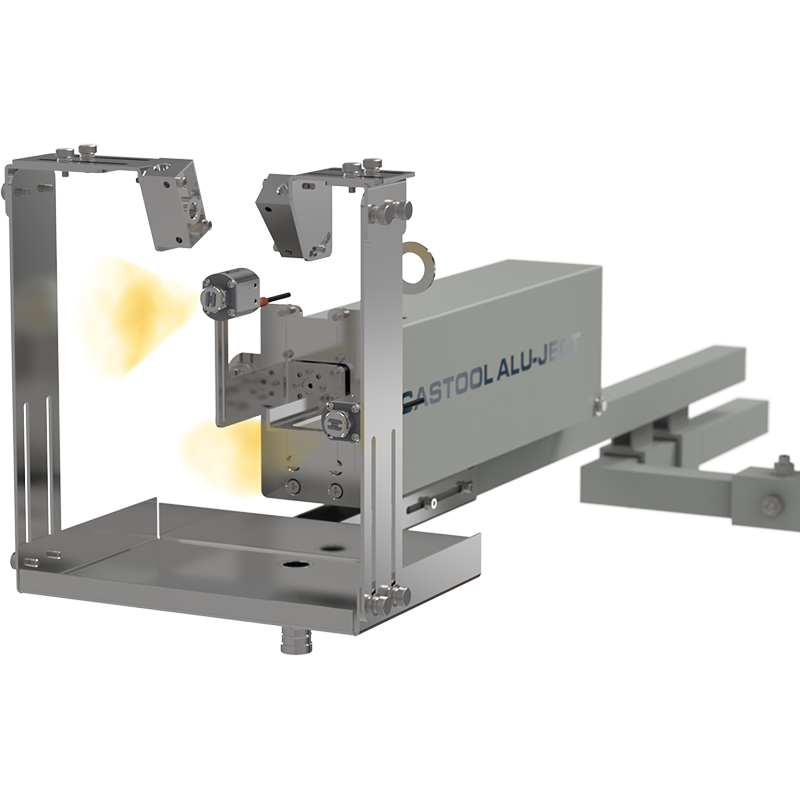

Castool Tooling Systems has developed a unique process of application of a liquid soluble lubricant to a preheated extrusion billet prior to loading into the press. The obstacle to their use was the Leidenfrost affect, which makes it difficult to coat a surface greater than 600ºC with a water based product. New binders have been developed which makes it possible to now apply water based lubricant to the billet.

The process enables improved coverage compared to boron nitride powder application with much less overspray and lower consumable costs.

At the end of each extrusion cycle, the dummy block must separate cleanly from the butt, without removing the section from the die, and without breaking the mandrel cone in the dummy block.

Aluminum sticking can be a serious problem, especially when using the softer alloys, and with larger billets. It is essential to lubricate both the billet and the dummy block to make separation easier.

Castool developed a unique process for applying a liquid soluble lubricant to a preheated extrusion billet or tool. The obstacle to their use is the Leidenfrost effect, which makes it difficult to coat a surface hotter than 390°F (200°C) with a water-based product. However, this application process enables improved coverage while reducing overspray and cost.

DILUTION

ALU-JECT is diluted by adding water to the lubricant

DILUTION RATIO’S

Typical dilution ratio is 1:3/ (ALU-JECT:WATER) and is recommended for initial evaluations. Actual dilutions will vary according to the application technique.

APPLICATION

ALU-JECT should be sprayed to achieve the best results. Spray application provides a uniform film thickness, which allows lower friction values, however the product can be successfully swab applied.