In order to increase strength to weight ratio of casting, the casting needs to be heat treated. The heat treatment temperature can go to as high as 400° C and for as long as 24 hours. The air trapped inside can expand and cause blistering during heat treatment, especially for aluminum alloy.

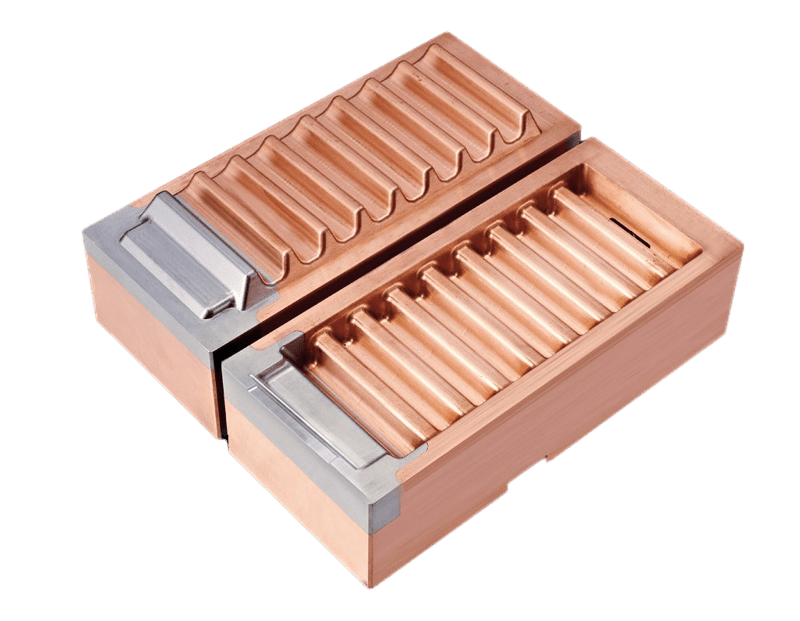

Chill Vents

Chill vents by InterGuss have an innovative insert design that provides high thermal conductivity, high temperature resistance which allows a large venting profile, and at the same time guarantees solidification of the aluminum or magnesium.

COST EFFECTIVE

The Castool Vacuum System is a profitable upgrade for your die casting process. Your present cost of rejected product due to porosity is known, and the time needed to amortize the investment in a Castool Vacuum System is easily calculated due to the increased mold life, and DCM life, that results from reduced shot pressure

In cold chamber die casting, the alloy is forced into the mold cavity with such force and velocity that small quantities of air and gases are often trapped in the casting. If the casting is structural, heat treated, or porosity sensitive, air or gas inclusions usually result in rejection. This impacts directly on the die caster’s bottom line. In today’s competitive market, this preventable problem is no longer acceptable.

The solution is the Castool Vacuum System, which ensures a consistent high-quality casting, and a guaranteed reduction in scrap due to porosity.

Before the injection shot occurs, a vacuum is drawn in both the shot sleeve and the mold cavity. The vacuum is maintained until the injection cycle is completed. When the cast is filled up to the chill vent cavity, the chill vent solidifies the cast and closes immediately. Almost all of the air is positively evacuated from the mold. A good vacuum in the mold cavity enables the alloy to flow into blind recesses in complex shapes. It also allows the front of the molten metal to merge freely.

A properly designed chill vent with improved thermal conductivity can increase quality and reduce scrap due to porosity. No additional water cooling is required. Also up to 20-40, 000 shots can be expected before maintenance is required. A problem that is shared by most die casters – the unplanned downtime that occurs when casting must be discontinued before the scheduled production run – has been eliminated.

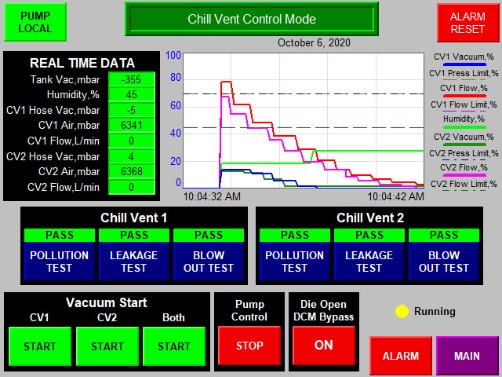

VCS-Unit250 High Capacity Vacuum Unit with Control System

The control system uses Ethernet based forward communication and operates on an optional 480 or 600 volt power supply.

- Vacuum is consistently maintained with an oil sealed rotary vane Busch pump rated at 1412

cu.ft/hr (40 cu.m./hr). - Standard tank capacity is 60 lmp. gal. (227.125L). Tank upgrades are available for larger

volume demand. - Floor space dimensions for the standard VCS-UNIT250 system are 42” x 27” x 75”

(106.68cm x 68.58 cm x 190.50 cm).

Purpose

- One of the major challenges for die casters is to eliminate porosity caused by air entrapment. The parts with porosity need to be rejected. The cost of rejection is very high and usually under estimated by die casters. The cost includes loss of production time and energy. A robust vacuum system reduces machine down time, production cost and energy. In addition, the casting will have high quality surface finishing.

Function

- Eliminate porosity

- Large venting profile provides maximum air suction

- Reduce scrap rates

- Enable casting of larger, thinner and more complex parts

- Increase product density and strength

- Reduce scrap rates

- Reduces scrap and unscheduled downtime.

- Aids consistent shot velocity.

- Extends life of shot sleeve.

- Extends life of plunger tip.

- Cooling can be automatically controlled.