The thermal stability of dies during the extrusion process has a significant impact on the functionality and life of the die. This makes it crucial to heat the dies properly before utilizing them. The innovative technology of Castool’s double- and triple-cell ovens is designed to save energy costs, time, and floor space.

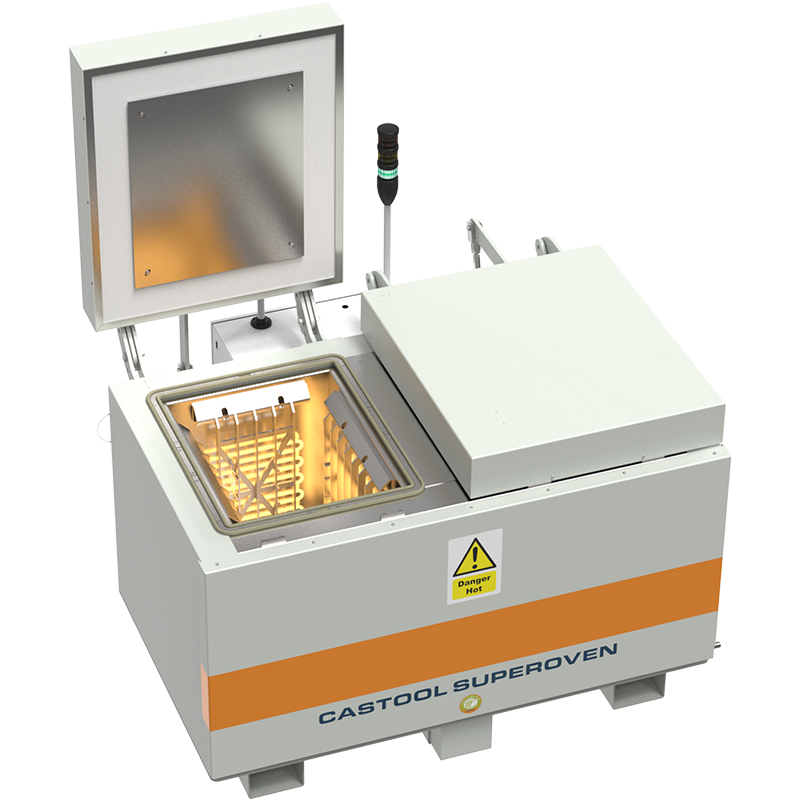

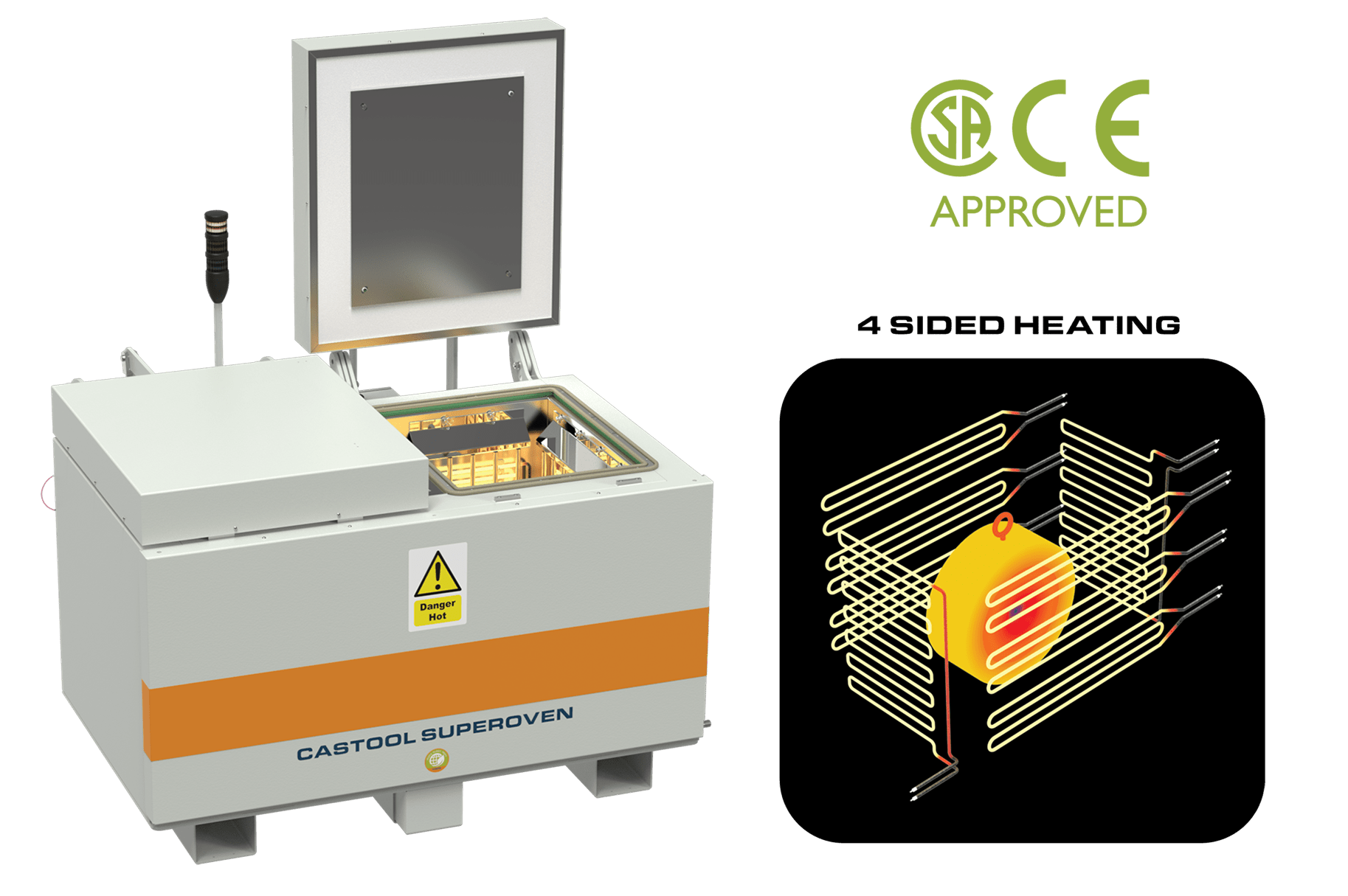

TCX 100/200/CUSTOM 4-SIDED HEATING FOR DIES 18″ (450 MM) DIA AND LARGER

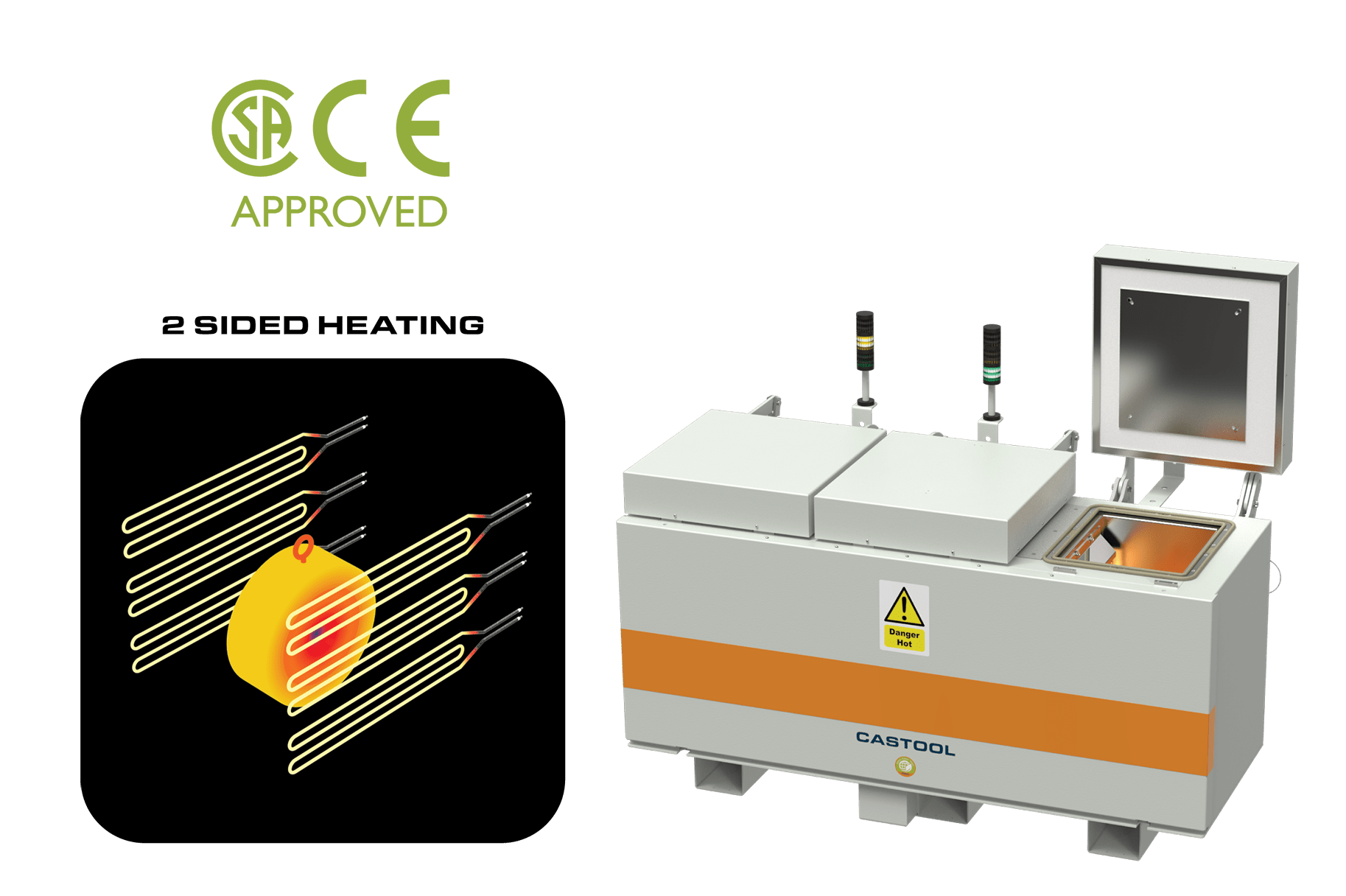

Castool found that in their die ovens where radiant heat was used, the rate of heating the die does not depend primarily on its mass, but more so on the amount of surface area exposed to direct radiant energy.

The innovative technology of Castool’s new SUPEROVENS features four heating panels instead of two, which can be independently operated depending on the ratio of the area of die faces to the outer diameter.

This results in an improvement of at least 30% less than the previous best time to temperature when heating large dies. The total amount of energy used, and therefore the actual total cost of heating the die is accordingly reduced.

If it previously required eight single cell ovens to service a press, the 30% increase in die throughput means that eight ovens can be reduced to six, with a corresponding reduction in necessary floor space.

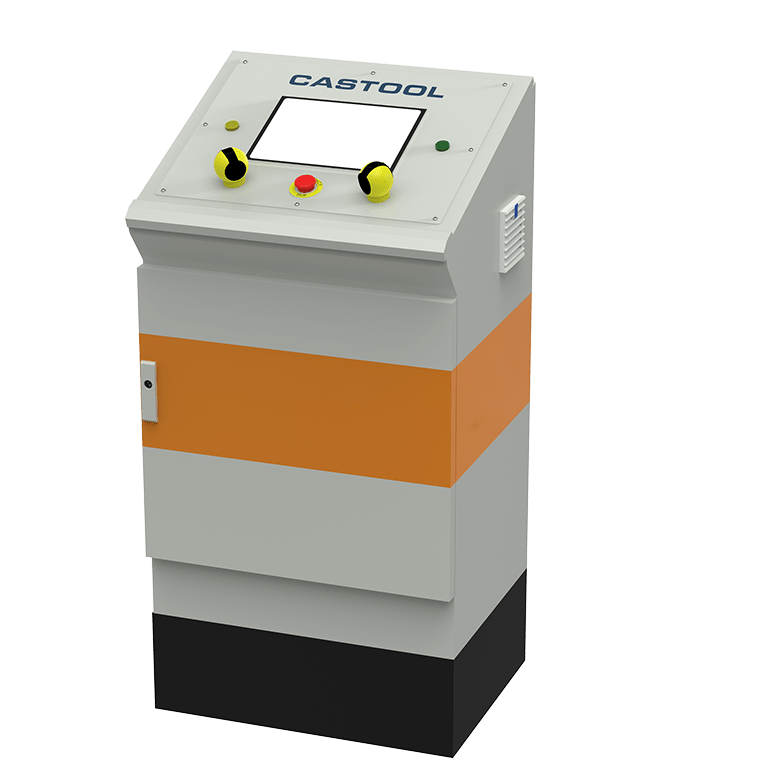

Each individual Castool die oven just now has an opening mechanism and a controller. The controller contains several algorithms, so that if you input the size of the die and the target temperature, it will then select the most appropriate program to heat that particular die. It will use the necessary heat head and soak time to heat the die most efficiently, and with the accuracy required. Castool has developed these algorithms over a number of years. They incorporate the number of kilowatts that are actually being put into the die, the radiant heat, what the heat loss is, the thermal conductivity of the die steel, and also what the surface area is that we can actually hit directly with radiant energy.

With that information we can accurately calculate the optimum heating cycle, and also the time to temperature.

A log of all die heating activity is maintained.

TRC40/50/60 2-SIDED HEATING FOR DIES 16″ (400 MM) DIA AND SMALLER

The Triple Cell Oven was developed for smaller presses with 8” diameter billet or smaller. It can provide up to 20 preheated dies per shift.

The Triple Cell Oven is very reasonable priced, has a small foot print, and comes with an integrated HMI and PLC 7” colour touch screen on a pedestal. It has the same 11-gauge 304 stainless liner, 11 -gauge cold rolled steel shell, ceramic insulation, and heating systems as Castool’s Superovens.

Maximum oven surface temperature of Ambient +35oC per CSA safety standard SPE-100 -13.

Control Options:

AB Micrologix PLC with 7” Colour Touch screen

Siemens 1200 PLC with 7” Colour Touch screen

Mitsubishi Q-Series PLC with 6” Colour Touch screen

Purpose

- Die to be equal to billet temperature for the first push, minimizing break through pressure enabling the use of high performance dies, reducing die breakage and eliminating start up billets

- Minimize die bearing oxidation and nitride layer degradation responsible for surface defects on the profile, shorter die life, and reduced die knock-off

Function

- To heat the die uniformly to within +/-5oC (10oF) of billet temperature in the minimum amount of time without over heating and softening the die steel or damaging the nitride layer on the die bearing.

- No billets wasted and scarp reduced by ensuring a die is brought completely to optimum operation temperature.

- Avoids the use of higher temperature first billets • The die is individually heated completely and uniformly to operation temperature so rapidly, that oxidation of the bearing is minimal, and bearing surface integrity is maintained to ensure optimum extrusion surface finish.

- Extrusion weight consistency (lbs/ft or kg/m) is improved by quickly reaching steady state thermal conditions.

- Dies are positively protected from overheating.

- Colored lights indicating the heating status of the dies. When the heating cycle starts, a yellow indicator light comes on. The controller shows “Time to temperature,” and begins to count down.

- Single cell ovens save money